I want a video of you pulling to at least 7k

i had one … but my camera saved it as only the first 2 frames. shitty i know

very nice work, saw this at work today t-up

glad to see its up and running.

cool. did you richen it up in boost yet

another question. sorry :). they way the ecu displays knock… has anyone done research in the SHO community to see how the ecu deals with knock.

reason i ask. ive seen naturally aspirated ecus only indicate knock once audible knock is detected… ie you hear knock in the car (ie bad) and then the ecu pulls some timing and indicates knock.

all turbo ecus that i know of, are much more sensitive to know and indicate knock and pull timing far before you ever hear it with your ears.

just something to think about seeing the condition of your old pistons.

seeing this thread makes me wish i had my sho still… but then i think of all the hassles of dealing with SHO specific stuff.

Brian

not really sure if anyones looked into how the sho deals w/ knock, but i also dont think that anyones had a problem with the ecu not detecting knock

now im wondering if we should swap in a turbo cars’ knock sensor and see if it changes anything. and for that matter datalog the stock sensor to make sure tweecer is displaying it correctly

also of note, i was poking around looking at the other pistons off the old engine, i think i looked at 3 of them, and none of them had cracked lands or scuffing on the sides, and since i grabbed the only one that was “clean” on the top … the oddball if you will … im wondering if maybe its the only with cracked lands for some reason

guess i gotta check the last 2 to find out for sure

but hey … on with the pics !

new cams, notice that with the smaller base circle theres no ramp on the cams … the leading edge of nose itself is what takes up valve train slack AS it starts to open the valve

the associated bucket, no signs of damage, at most theres “slightly more wear” where the shim seats around the edge, but definantly not a large amount of wear

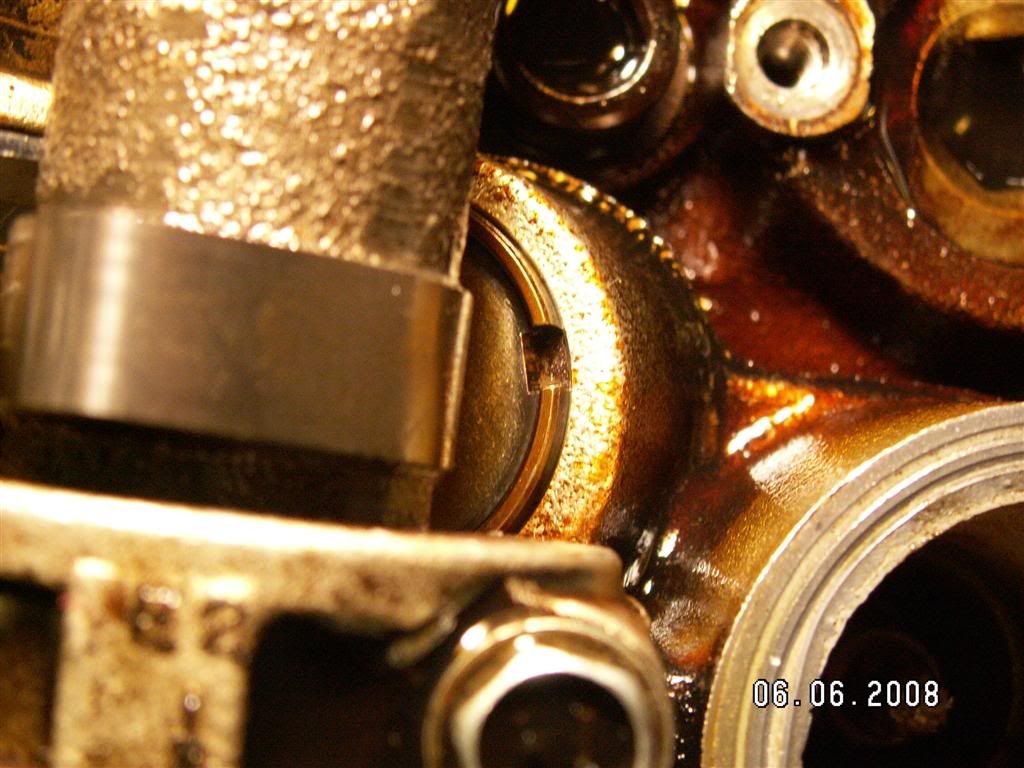

theres the knocking noise ! cam geat was still fully seated against the cam, and the bolts still had WAAAY more thread left. bolt holes still had all their thread and threaded in without any problem what-so-ever. the knocking noise was the gear rotating and tapping the bolts, no signs of the cam gear having rocked away from the cam

valve cover back on … yay !

alex passed out on some cardboard while i work … boooo … at least hes not using the gas can as a pillow anymore …

intake back on … yay again … i forget to tighten the intake bolts, booo again

hey look, a sho engine in something else !!! (dont bother trying to poke around for the rest of the pics, lol)

better pic of the intake on … and yes thats a sledge hammer holding the hood up … last line of post 46 in this thread (reliant_turbos’ reply) should explain why a sledge is used, lol

and yes thats the burnt engine cover and DIS module being reused … battle scars are sexy

Team bootleg does it again :tup:

someone tell alex that the turbo sho needs MOAR NAWS !

and by more, i mean “installation”

keep the stock knock sensor. it is matched to the ecu and to the engine knock frequency characteristics. its just the level (voltage) that the ecu determines that is knock that is in question.

you could make a detonation can/earmuffs setups and listen closely and watch tweecer to see if you are getting indicated knock. if you dont

hear barely anything in the earmuffs or the slightest tick and tweecer indicates knockm then the system is working to a safe level.

Brian

well the stock sensor mounts right next to a steel plate in the valley … a rather large steel plate at that …

could easily replicate it with some 3/8 plate , throw some threaded holes into it, make a wiring harness, and datalog the results from the sensors while listening w/ the ear muff setup

i can do 4 extra sensors at once through tweecer (get plotted right to the tweecer graph) or i can do 8 extra sensors to a seperate graph

that might work but its hard to datalog knock sensors without an oscilloscope or something with a really high sampling rate.

i dont know about all ecus but i know that turbo chrysler ecus have additional circuitry to “store” the peak of the knock signal using a capacitor after every ignition pulse so that the ecu can easily read it without having to deal with the small window of time when the knock occurs and then it clears the capacitor to ground before the next ignition cycle. here is a diagram.

http://www.squirrelpf.com/bucar/ecu%20stuff/85_86_87_detonation_diag.gif

without some additional circuitry, you are going to need a scope. you might be able to get away with a PC soundcard scope setup and do FFT analysis after the fact to determine the frequency.

the other think you need to know is if the knock sensor has a flat frequency response and the filtering is done in the ecu or if the sensor is tuned to a specific frequency. my sensor is sensitive to noises in the 6000-6300hz range. i dont know what sho sensors are or if the ECU does filtering.

basically, i wouldnt try other sensors on the engine as they probably wont be sensitive in the right frequencies.

Brian

Wtf are you guys talking about lol you too def know your shit, well atleast you should like ya do :tup: i just wanna see it run 11’s

Shit even 12’s reliably!

So, maybe we’ll get a run in this year? The family car shootout is goin’ down…lol

Good to see it running again.

a search of shoforum shows that the knock sensor is tuned someplace around the 7000hz range

i posted a thread w/ your questions, ill see if i get any reponses to it

cool.

well, i got an answer about the knock sensor, but i dont think its much of an answer. you were asking about how “quick on the draw” the sho ecu is, instead i got an answer about what the sho does “after the draw” so to speak

yeah, its setup for safety after a knock event occurs. is there a table that defines knock sensor voltage vs rpm or something like that?

i guess youll have to do some sort of test like described earlier.

Brian