Decided I didnt like the oil drain for a number of reasons, so I decided to make a new one. I wanted to try and do it all stainless without any rubber tube.

Started scouring the internet and discovered a flexible stainless oil drain tube for cummins diesels. Picked one up for $40 figuring I could mod it to my needs.

I didnt get a pic of it, but it started off life like sorta like this

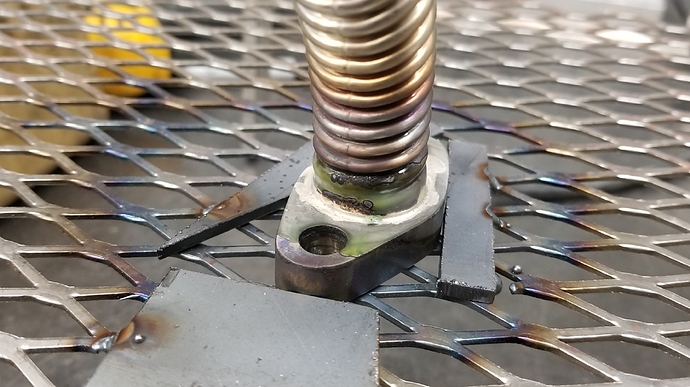

First the turbo flange was too large, so I welded up a new one out of two pieces of 3/16 ss plate. I only used two pieces as I had it and didnt want to attempt to bore ss for the tube connection.

After cutting the flange off of the flex tube I brazed it on with silver solder. This was a challenge as I had to preheat the flange since it was so much thicker than the tube (tube was like 0.010" wall), then set the tube in place and then continue to heat and add the silver. In the end it turned out great. Obv I smoothed out the edges of the flange at this point also.

Flux cleaned off and wire brushed. I was very pleased at how well this turned out.

Flange sanded flat

Then, since the hose was too short (on purpose) I needed to add a straight section to it. For this I used a section of 5/8" 0.030" wall stainless that I swedged the end of to fit in the end of the flex section. This was then also brazed together. This was much easier with the materials a more similar size.

Cleaned up.

Skipping a few steps here, but I welded up a few 1/2" schedule 10 bends to attach to the pan and extend up over the axle and added a mounting tab for the block.

Machined wrench flats to the male bung

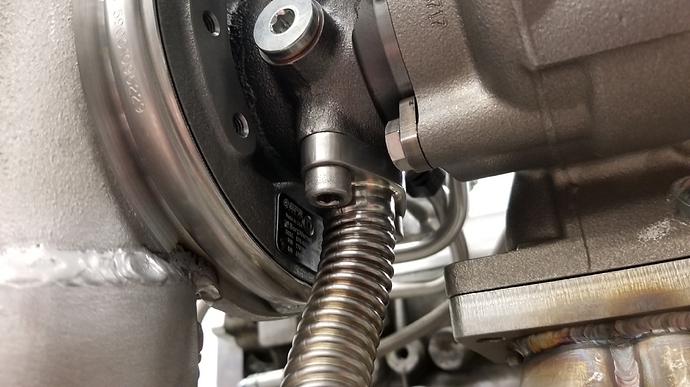

Close up ish of the tube assy, the end will weld to the pan.

The straight section attaches to the pan section with a tube nut / sleeve -10 connection.

Finally, the whole assy in place.

About all thats left is to weld the S bend to the oil pan once i pull it off and get it cleaned up.

Dan

Started smoothing mold lines on the trans. Some of them were just stupid bad…like they could cut you so bad youd wish they didnt cut you so bad.

Still a bit left to do, but its a huge improvement for just two hours of work so far.

Dan