Up next was modifying the Reiger lip I bought forever ago and skinning it with carbon fiber.

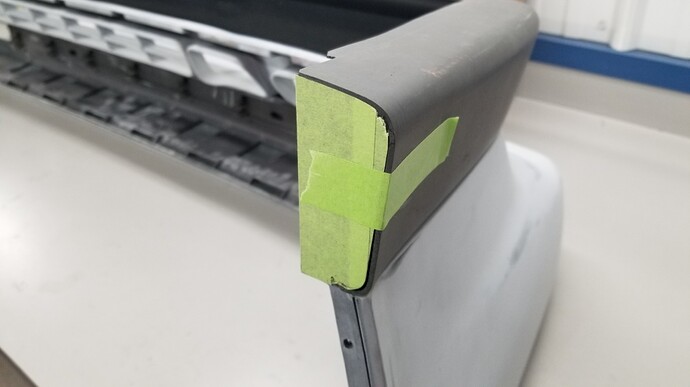

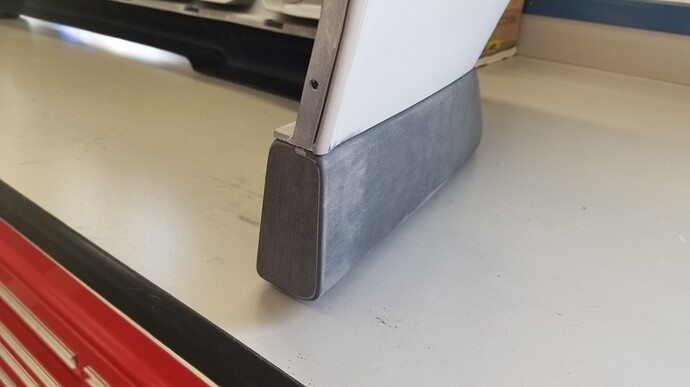

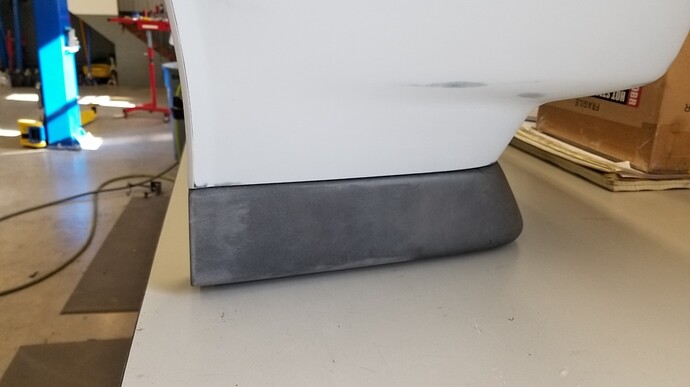

First step was to cap the ends because its how it should have been. I had to trim the excess at the ends to match the inner arc of the wheel

opening on the bumper (not shown).

Then I cut out some 3/8" thick ABS panels to cap the ends.

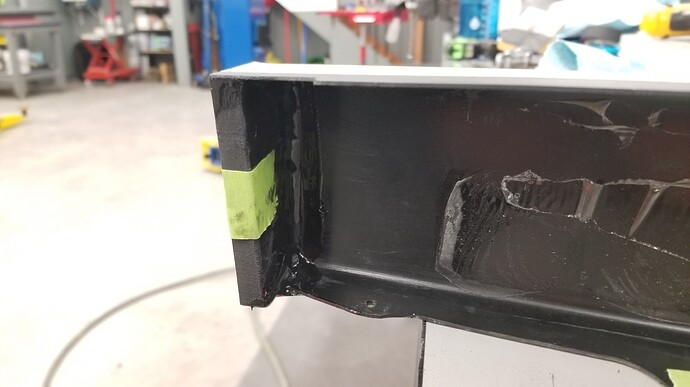

And bonded them in place

Once dry I sanded them with a nice bevel all around.

With that sorted and trimmed up nicer than Reiger could bother it was time for the carbon skinning.

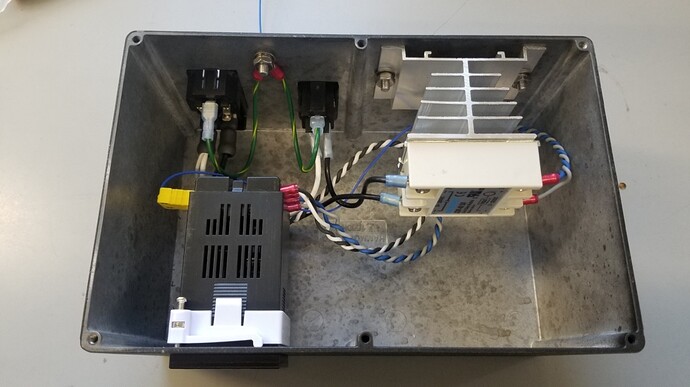

First I needed to make a warm box for it to cure in as I only keep the shop 56 in the winter, and the resin needs 80 degrees to cure

correctly.

I grabbed a few sheets of 1/2" foil foam and a small 1500W $25 electric heater from lowes.

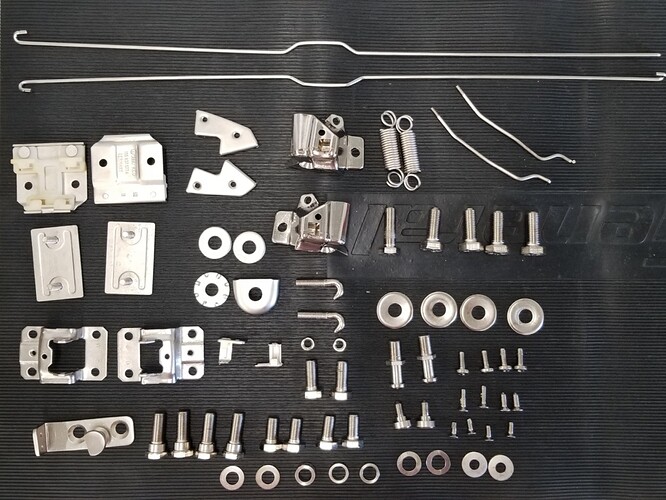

To keep the temperature in check I built this little PID control box with a 40A SSR.

Here is the taped up box wit the heater and PID box. Also made a little 2x4 rack to hold the lip during the skinning process.

Now for the acutal skinning.

First a layer of resin is applied and at just the right tackyness the CF fabric is stuck in place.

Then several coats of resin are applied on top.

Here we are a few coats later, and the back edges trimmed up.

And then sanded the first 3 coats of resin flat.

Here we are mid process

And sanded out

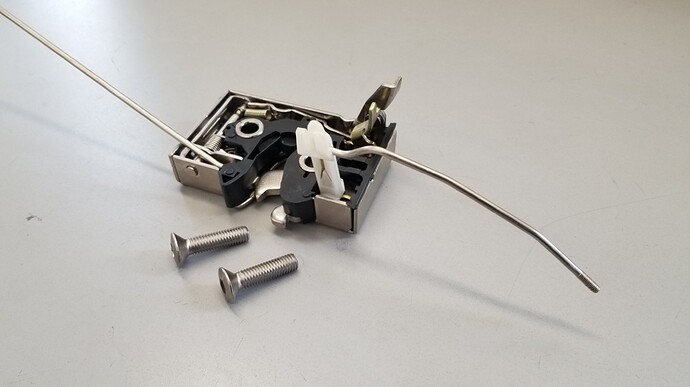

During this process i noted there was a pocket where the CF didnt stick to the abs.In order to fill this I ground out the back side and poured in some black tinted resin.

It worked perfectly.

With that sorted I applied a final coat of resin.

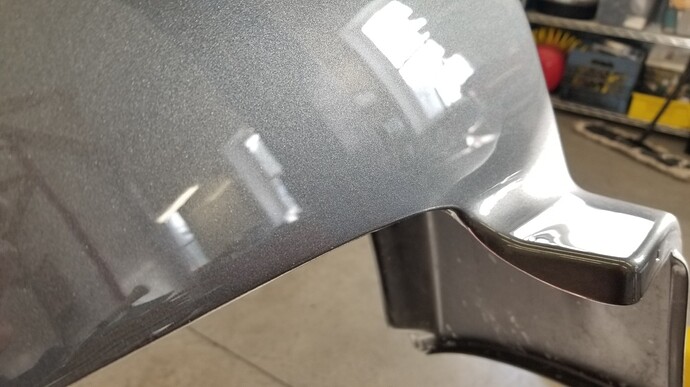

Then this was sanded flat to 800 grit, and then the clear coated the same as the car

Right off the gun

And then this was again sanded flat to 2000 grit and buffed. For this I used my 3" Rupes with a microfiber pad with Meguiars 105 and polished with a white foam pad and Megs 205

Final result.

And that ends November.

Dan