Background:

The 91-99 turbo DSM’s came with a water cooled oil filter housing. The water cooling was incorperated by using an oil filter housing that was similar to the 1g non-turbo oil filter housing. The difference between the two housings is that the threads for the oil filter were cast with the housing on the n/t cars while the turbo housing was female threaded. Mitsubishi designed a sandwich adaptor to go between the oil filter and the housing which would have engine coolant run through it. This makes the oil travel across the water cooled surface of the sandwich adaptor and through the filter and then back through the bolt that holds it all together. Which in turn cools the oil to engine coolant temperature.

The Problem:

Although this system does work it has a flaw. The bolt that holds the oil cooler sandwich to the housing comes loose over time from oil changes or vibration or a combination of the two. Whenever an oil change is done the oil filter is removed which can unthread the oil cooler bolt. There have been way too many casulaties(motor wise) from the oil filter coming loose.

The Fix:

Stopping the oil cooler bolt from coming loose should inturn keep the whole assembly including the filter tightened to what you left it at. To keep this oil cooler bolt in one spot we are going to add a lock almost like a castle nut and cotter pin found on a ball joint.

The Steps To Remedy The Problem:

Step 1.

Remove the oil filter.

Step 2.

Torque the oil cooler bolt back down, 35 ft/lbs seems to be the magic number. You will need a 24mm socket for this.

Step 3.

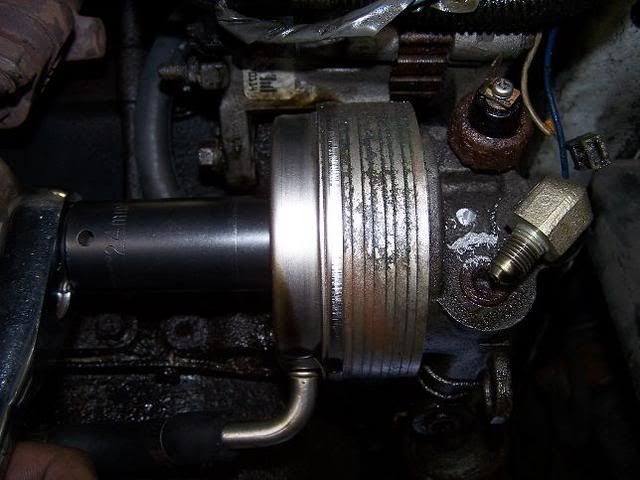

Drill the housing in the center of the curved part (as pictured below) with the bolt still torqued and using an 1/8" drill bit or smaller. You will notice the difference of when you get through the aluminum housing and hit the oil cooler bolt. DO NOT DRILL THROUGH THE BOLT! You just want to mark the bolt with the drill bit.

Step 4.

Remove the oil cooler bolt and remove the oil filter housing for tapping and cleaning. (To remove the oil filter housing the lower timing cover has to be off, so it is best to do this during a timing belt job.)

Step 5.

Tap the housing. You can use what ever size tap you would like just be sure to stay around the 1/4" or 6mm tap size and follow the directions of the tap kit. (I use 6m x 1.0 thread bolts as they are abundant after working on a DSM)

Step 6.

Pick up your oil cooler bolt and locate the mark from drilling the housing on the car.

Step 7.

Make a groove in the bolt with the drill bit you just used for the tap. Then clean the threads with a wire wheel and then clean the whole bolt with soap and water.

Step 8.

Find the bolt that you will be using and slightly round the beginning threads of the bolt. As you can see the bolt thread do not need to be longer than 12mm.

Step 9.

Clean your oil filter housing in soap and water after removing all sensors and the oil pressure check valve.

Step 10.

Put the oil filter housing back together and back on the car with a fresh gasket.

Step 11.

Get a good light and watch through the new threaded hole in the housing for the dimple in the threads as you tighten the oil cooler bolt back down. After the dimple is lined up the with hole get the bolt that you are using to thread into the housing and put some RED Loctite on it. Tighten this bolt to about 21 inch/lbs. Put your timing covers back on and the oil filter and have at it.

great write up.

great write up.