Going with EVO brakes. They will be mounted on spoolin69’s zinc-plated 1g/2g caliper adaptor brackets.

Shane’s kit came with all this, bolts and all.

This is what normally holds the stock caliper to the knuckle on a single side.

This is what replaces those two bolts in Shane’s “kit” and holds the evo caliper to the knuckel.

The calipers need clearanced, an existing hole needs tapped, and because I’m a '97 I need to grind the knuckle down some near the lower ball joints. If I had a 90-94 or a 95-96 I wouldn’t need to grind anything off of the knuckle. But I’ll explain all that later.

The zinc-plated, laser cut steel is STRONG, not sure what grade of hardened steel it is exactly, I’m sure Shane will chime in with that but all the bolts are a high grade.

---------- Post added at 10:07 PM ---------- Previous post was at 10:07 PM ----------

So after sitting outside for over a year, the Talon finally got pulled out of the elements and into its new home. I have to remove the critters that call it home, replace the parts that were sold off the once running car when times got tough. No ETA when it will return to running status, although I was eyeing up some nice aluminum jack stands from HF.

It got trashed from sitting outside for so long.

What I have on my hands now it my very own “Barn Find”.

Interior is worse than the outside.

Lesson: Don’t just park your car, come back years later and expect it to be ok.

I decided that I’m going to set aside time on Sundays for working on the Talon, so we’ll see if I can awake her from her slumber.

1st thing to address is that I can’t even get into the car because both the door handles are broken off! To fix that I got the door handles removed, the one bolt is a PAIN when it’s rusted solid. Ordered the Rcaz metal inserts and got to work. ROOK hooked me up with some good 2g handles that were already black.

The Rcaz site has the “how to” on the fix so no need for tons of detail. Basically remove pins, band saw, and epoxy, install inserts then re-pin.

Not real sure what this picture shows but here it is. I have to get back into the swing of build thread picture documentation.

Next problem I guess is that I sold off the GM MAF and translator, so I have to set up speed density before attempting to start the car. Since I won’t need the meth port on my TB elbow (mild steel welded into stainless piping) for some time, it seemed like that spot was going to be best for my IAT sensor install. So I’m going to be drilling that out an welding in the new S.S. bung.

Just finished up modifying the door handles, they turned out great. The seem really sturdy I shouldn’t have a problem with them breaking once I have everything adjusted correctly.

And got my hole drilled for the AIT sensor in my UICP. I’ll just have to get that welded.

I hope I do a nice job on it, even though I’ll be powder coating all the piping in the end.

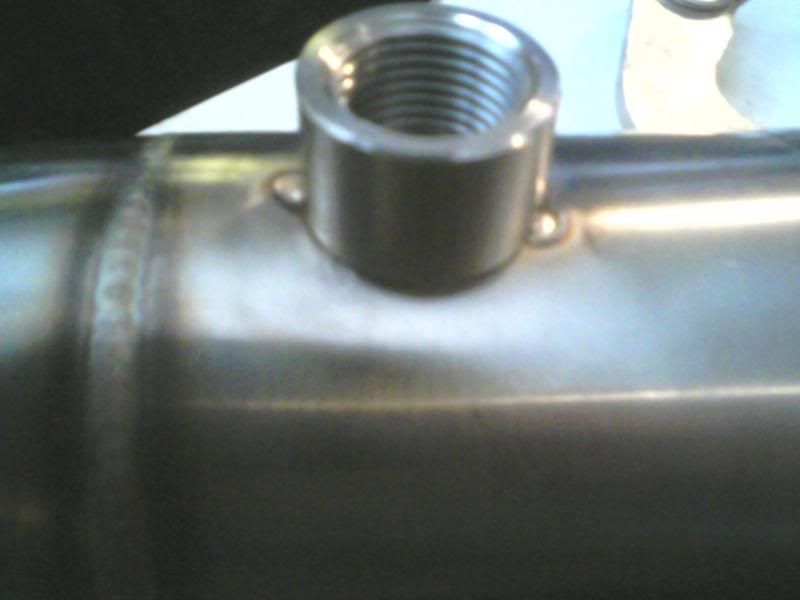

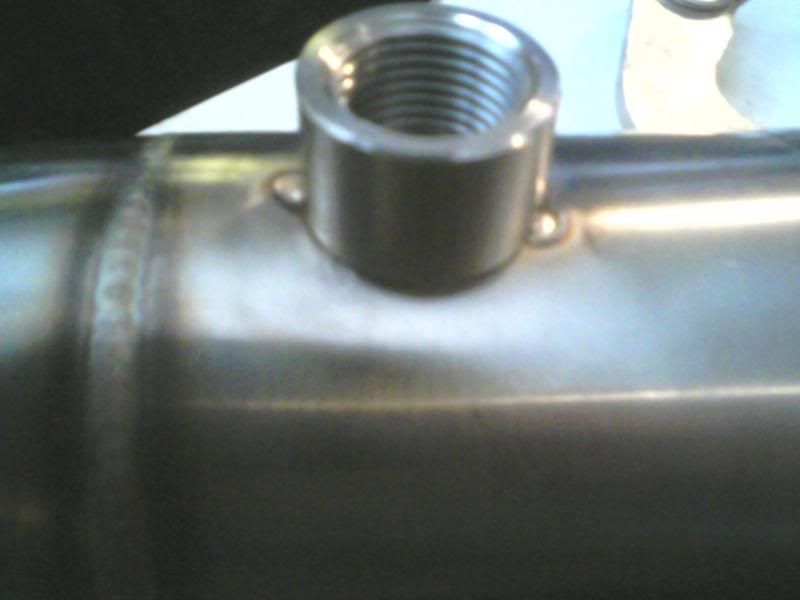

Well I had the welder out today so I decided to weld up the Stainless Steel AIT sensor bung in the UICP.

I haven’t welded any stainless is some time and was REALLY nervous about messing up.

Clamped it.

Tacked it.

And worked my way around slowly trying to let cool in-between.

Finished. Its not perfect, but its hard to compare with the absolutely flawless welds Slowboy did when making the rest of the intercooler piping. I’m happy with my work.