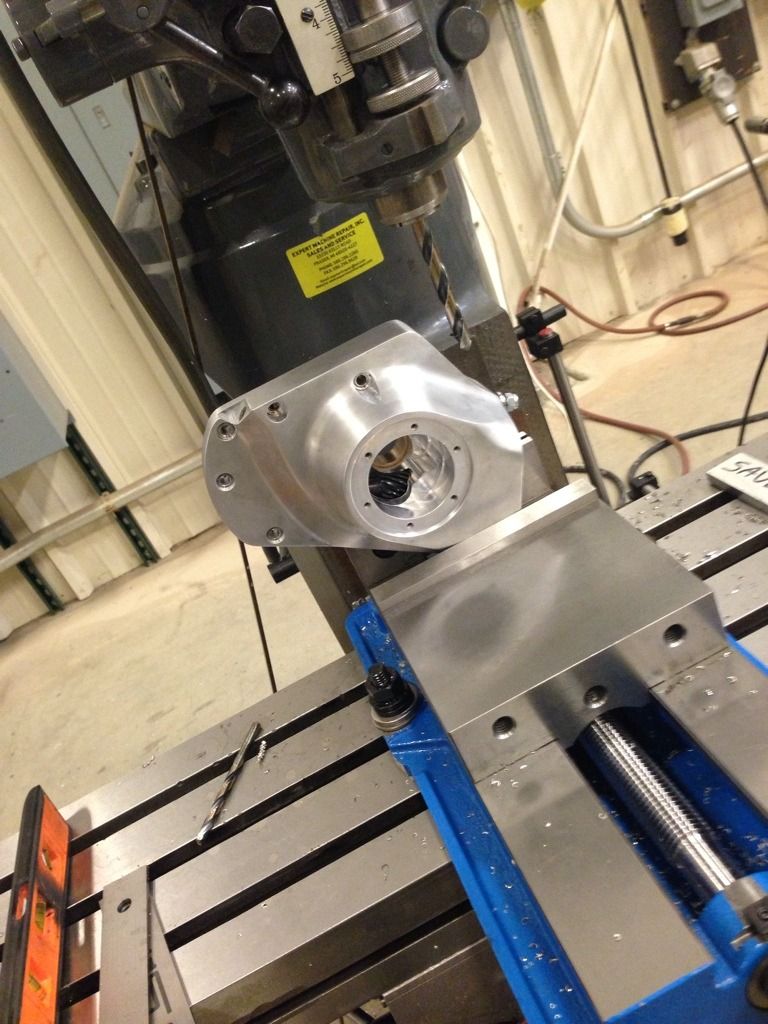

Wow that was fast! I may have had the screws you need. The water jet shape made making that part a bit easier on the Bridgeport no?

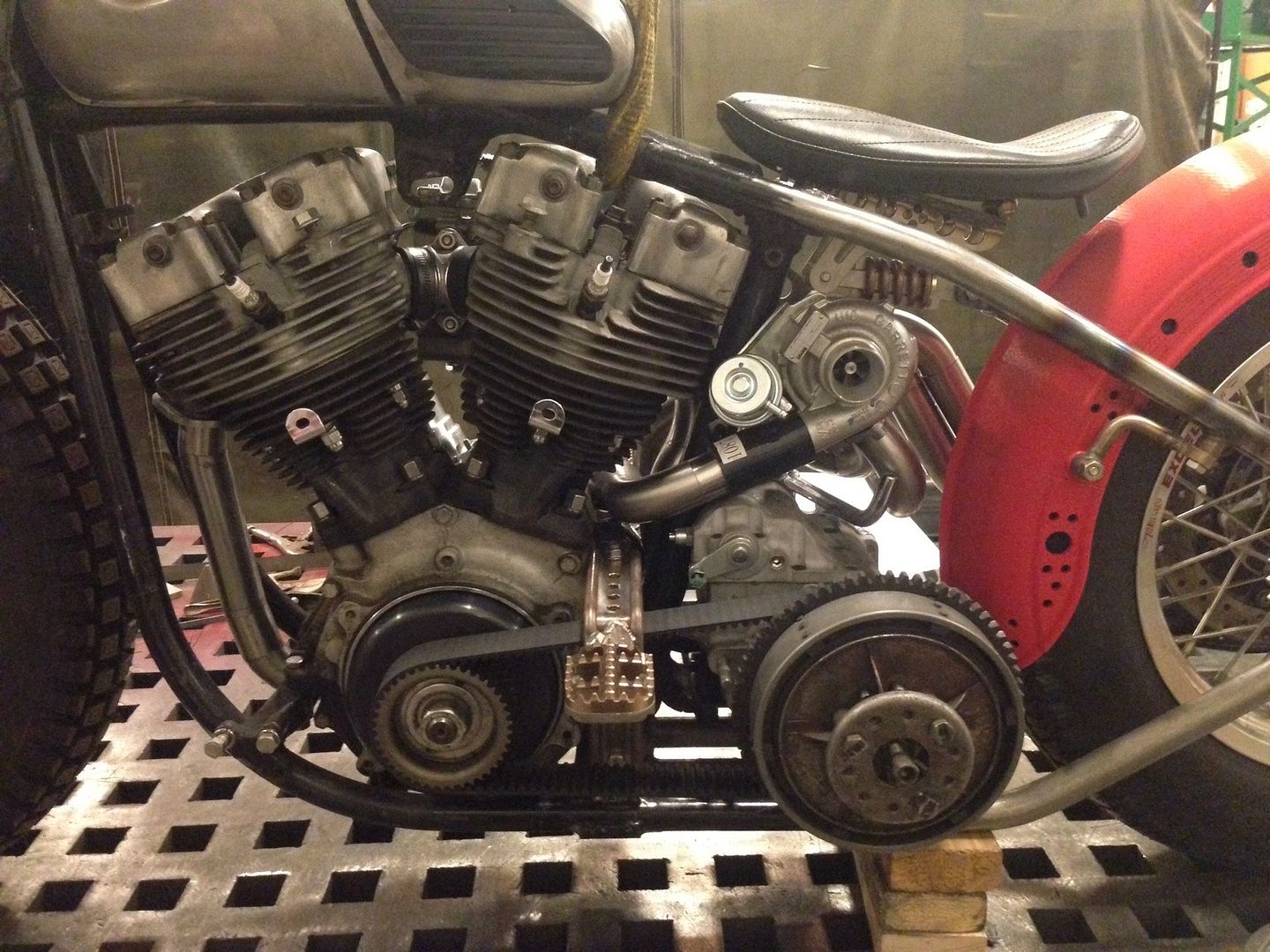

I really dig this project start to present.

This is really going to piss off some die hard, old school harley guys. Love it.

Sweet pictures!

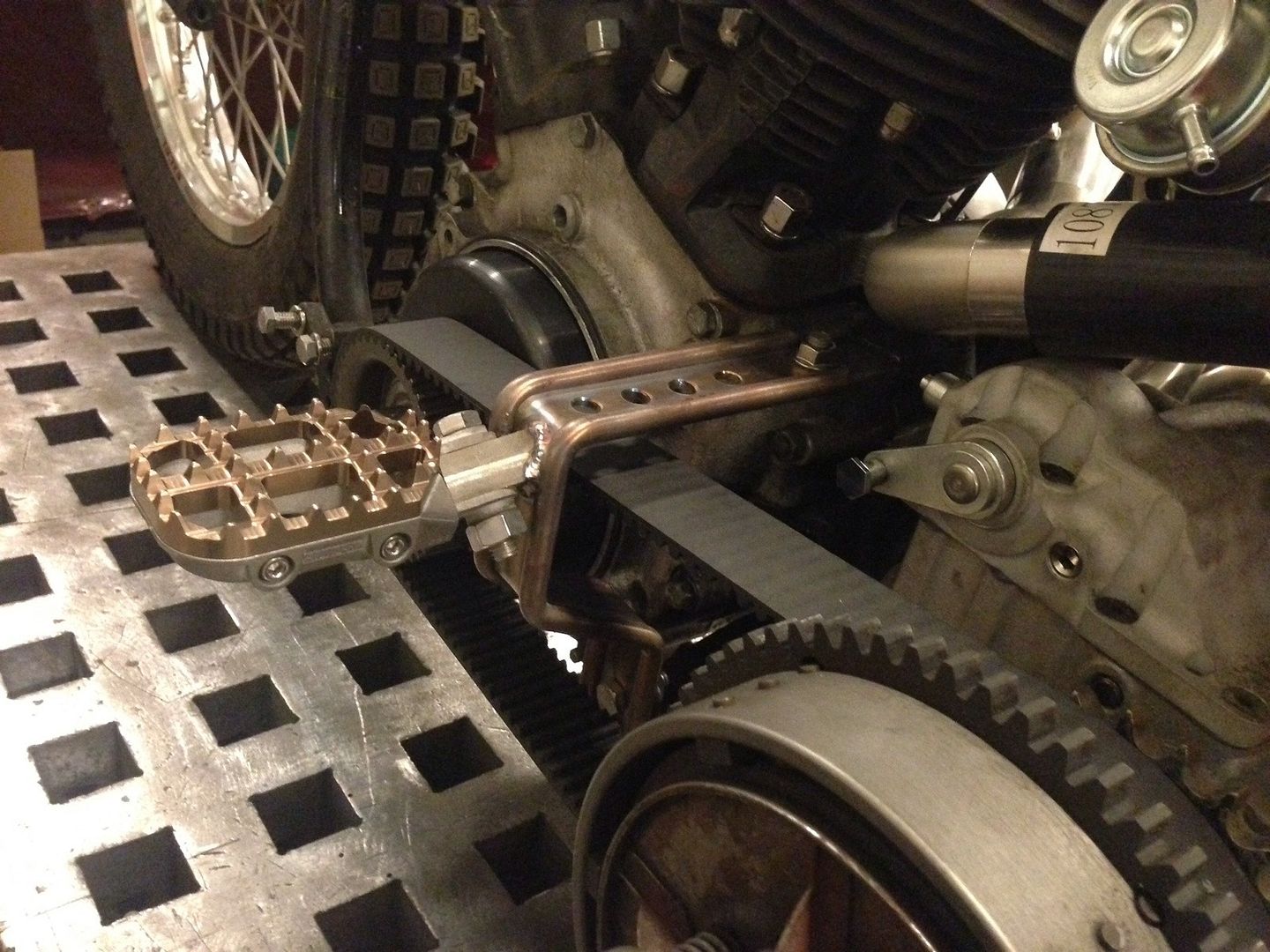

So I spent about 20 hours making footpeg mounts but I think I made them too wide, so I am going to remake them about 1.5" narrower.

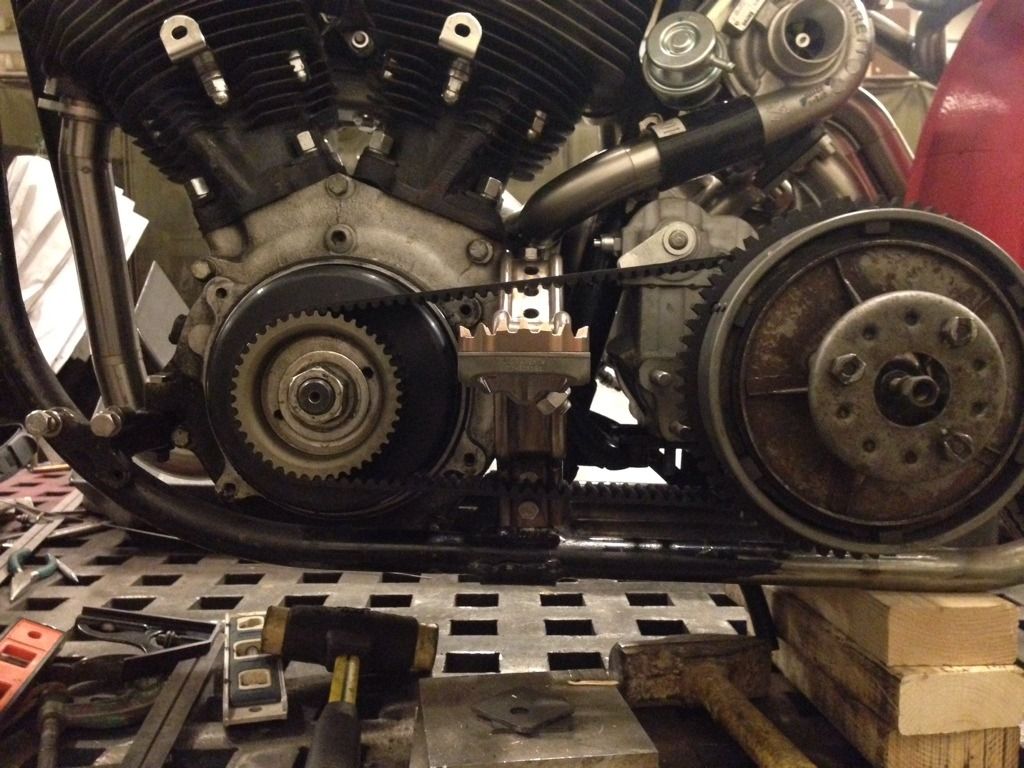

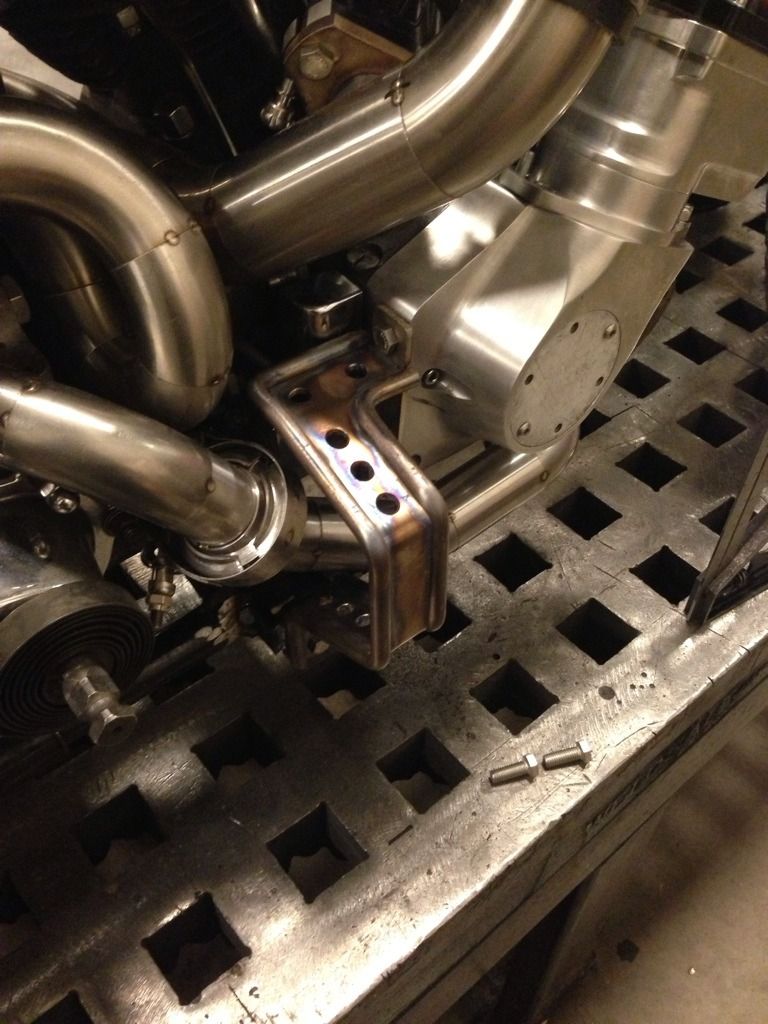

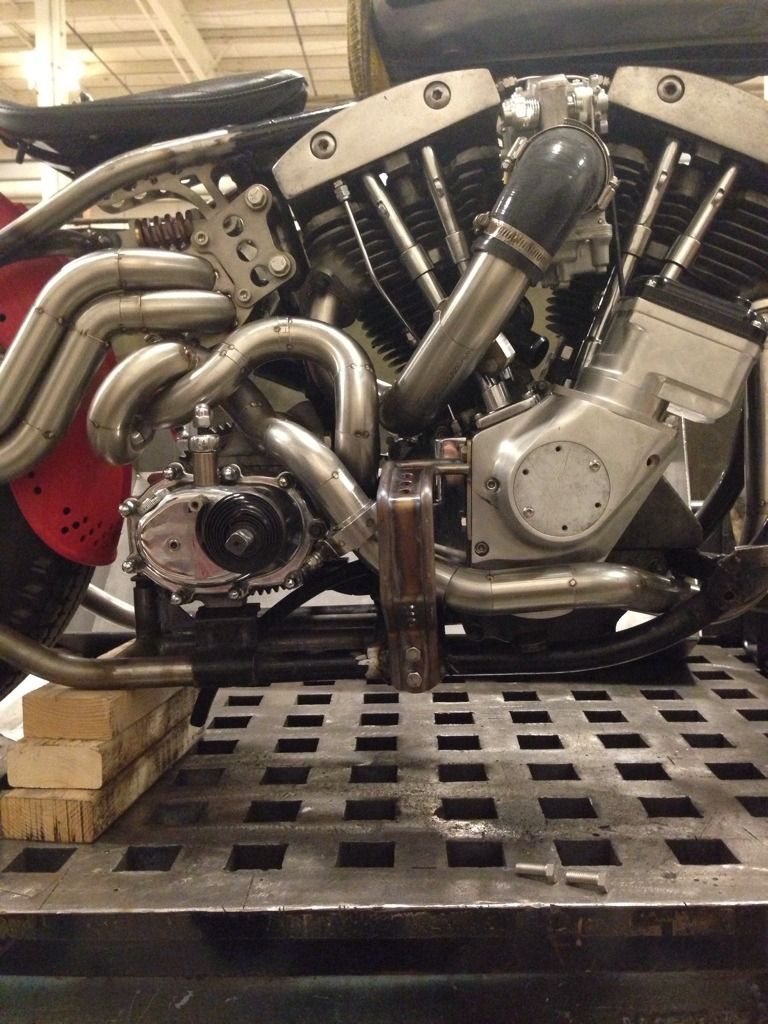

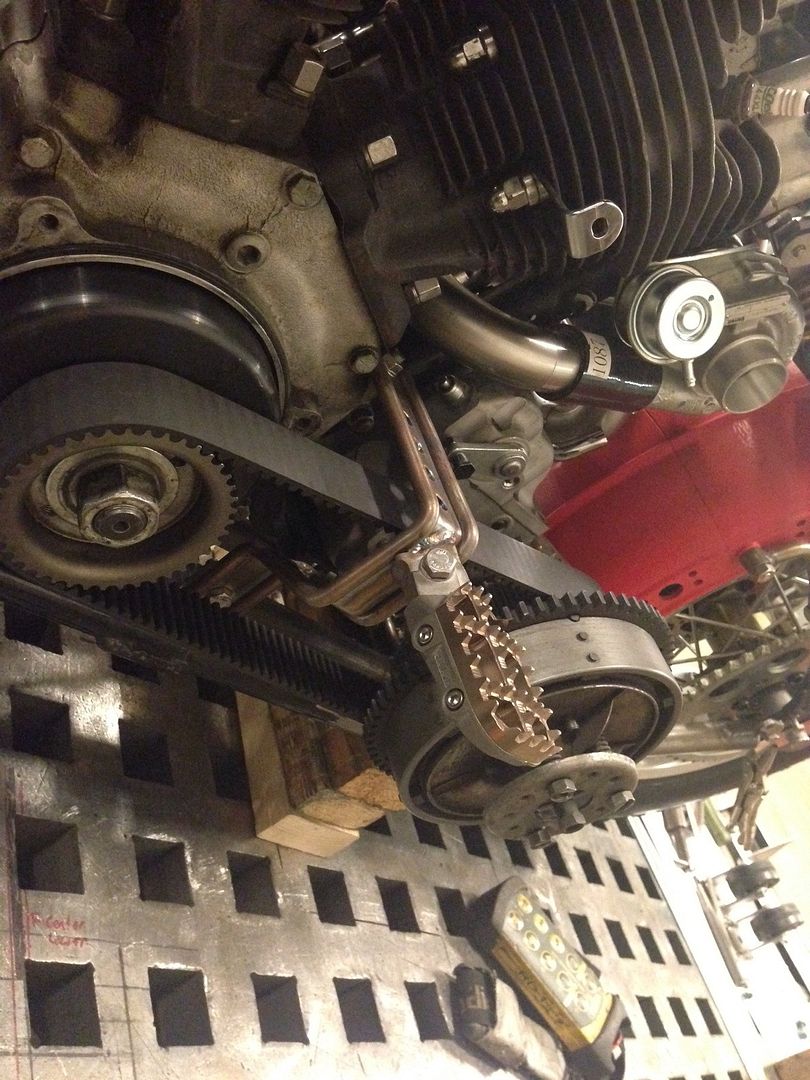

SO much work making these. The belt side I modified (read: beat with a hammer) the bends after welding them to give me more belt clearance and they got kind of tweaked but the right side came out perfect. Hopefully the second round they will both be dialed.

Here’s the sort of messed up left side:

Before I attacked it with a hammer it was very square. It’s not something you’d really notice while looking at the bike from any normal angle but it’d drive me nuts. Working with plate and bar is very time consuming to form and fab.

The right side didn’t have anything good to mount to so I drilled and tapped my 1600 dollar mag housing…

And so the Harley oil leaks begin! ![]()

LOL, he’ll probably fab up some crazy looking drip-pan that automatically drops down from the frame when the kickstand is deployed.

Haha. There is no gasket on the magneto.

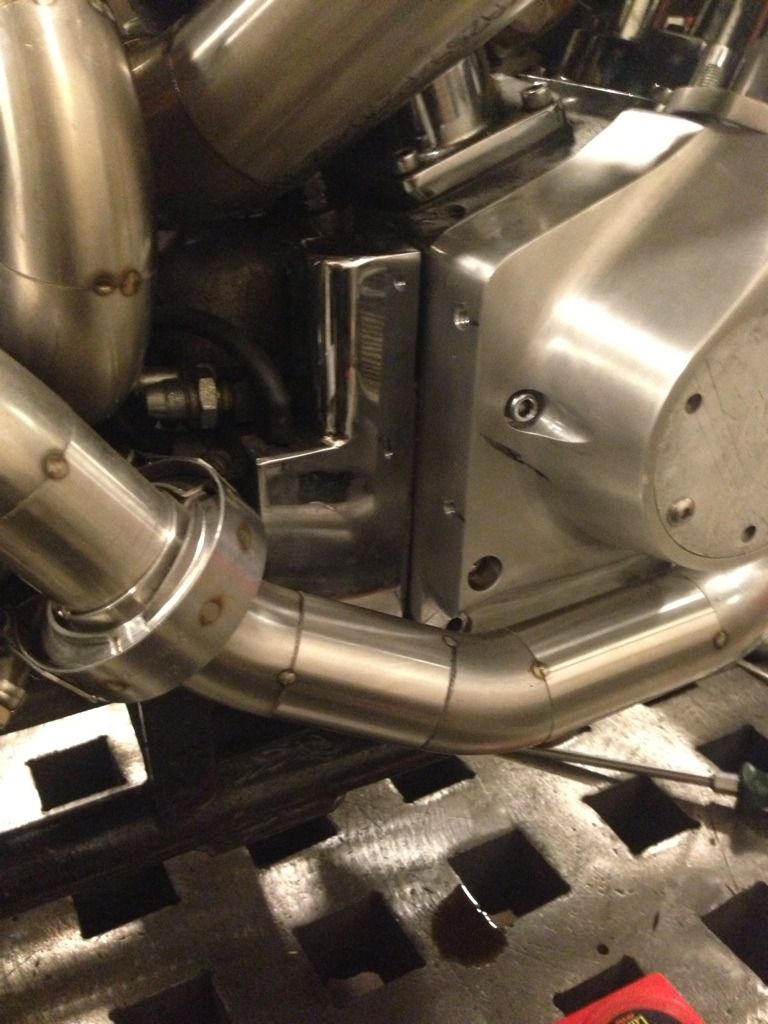

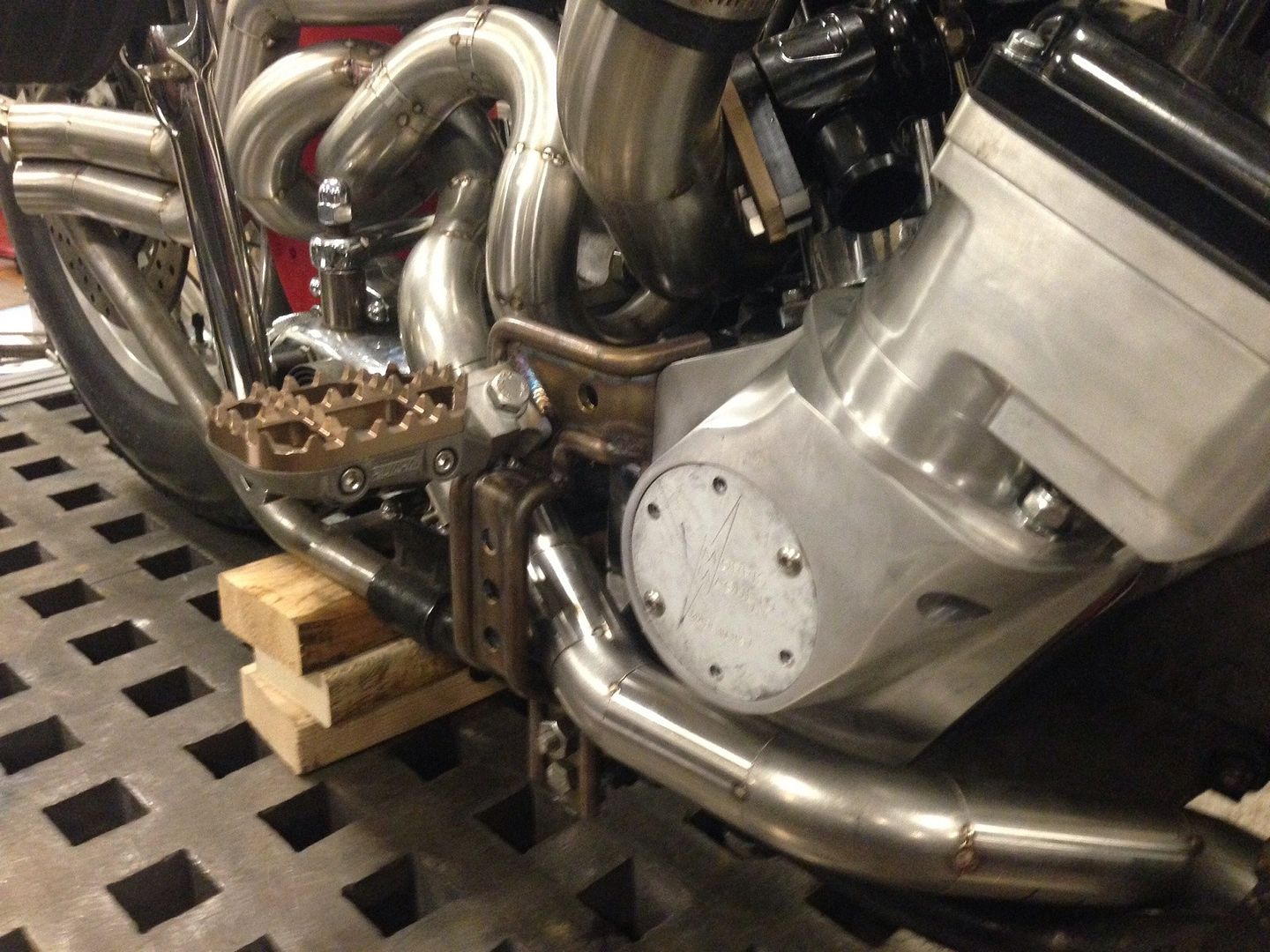

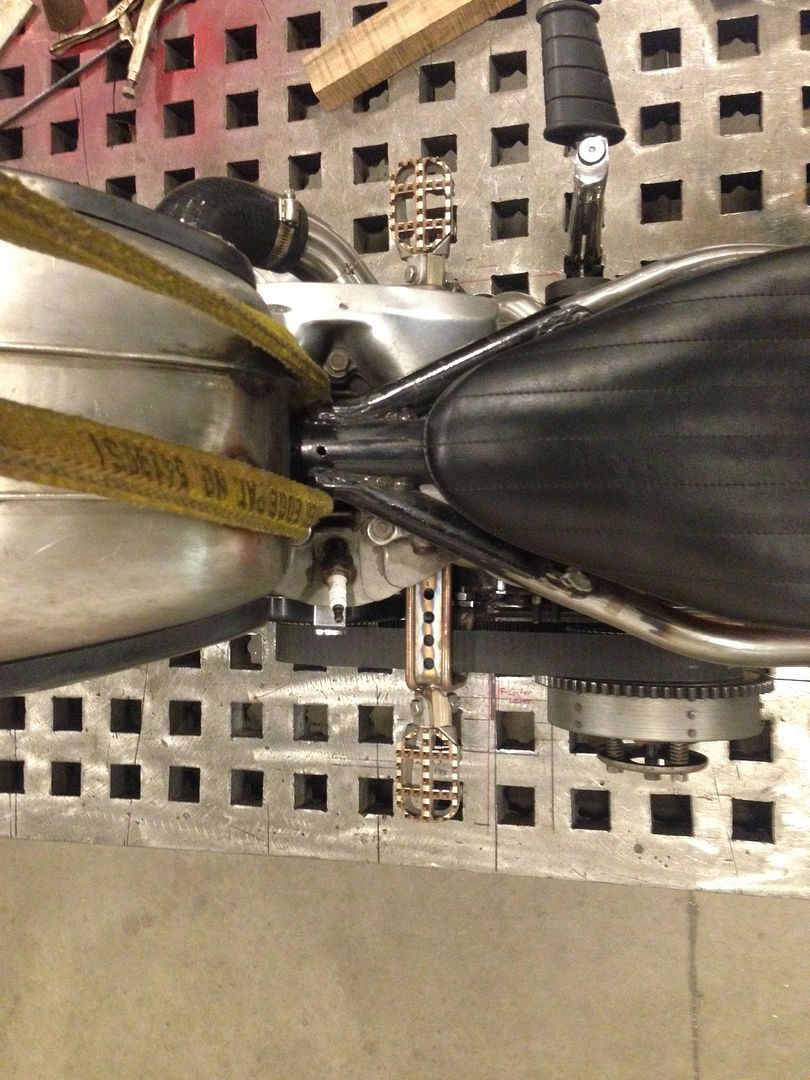

I felt like the footpeg mounts were far below my quality threshold, so i remade them, raised them, and brought them in. Here’s the result. They are pefectly straight, square, level and symmetric. Next step is to add in some controls. I have literally about 35 hours into this part of the project between the two sets. Doing custom work (the right way) is so time consuming. Made from stainless and tig welded. I love the color of welded SS so I won’t polish them or anything.

:tup:

:tup::tup:

I don’t understand why gifted people like yourself work for others

That’s quite the compliment. Thank you.

The answer is that I don’t think I could deal with the stress of working for myself, really.

Love this thing! What’s the list of things needing to be completed? How much time is the contest giving you?

Supposed to be done by June but if it’s not done… Oh well.

Here is a clutch pedal I made from 316SS. Got a bit of chatter on the groove but it’s not noticeable enough for me to remake it. The peg is actually 5 titanium men’s rings (eBay special, complete with a fake diamond) slid over an aluminum peg that I machined. Next will be to add some bearings and a shaft support to the left side peg mount that I made last week.

Cool idea!

:tup: to originality!

Spoken like a person who has found their passion. Good for you.

:tup:

some really cool engineering. will this have a boost gauge?