Nah, maybe just for the dyno.

So I’ve been doing some thinking about caliper leverage. Since I have a weird combination of caliper and master cylinder, I needed to do some math. This is pretty vague math and there are a lot of assumptions I am making but I will compare my results to what I think it SHOULD be and go from there. The master cylinder I got is a pull-type master and pretty hard to come by, so I’m stuck with this sort of aggressive bore size (17.3 mm)

KNOWN:

I haven’t weighed my bike but I suspect it weighs 350 lbs. I add another 160 or so, plus fluids, so 525 lbs is my GUESS.

I hate doing anyforce calculations in Imperial units so:

M=525lb = 238kg

A little internet searching yields a rough coefficient of friction of .40 for average brake pads, so:

Mu = u = .40

Picked a stopping distance for a Honda police motorcycle because it was a roughly similar weight:

60-0 mph in 140 ft or

Vf= 27m/s

Xb= 46m

Caliper piston size: .027m x 2 & .03m X 2 (Total area: .0026m^2)

Master cylinder size: .017m = .67in (.364 in^2)

First we can calculate the negative acceleration:

Vf^2-Vi^2=2ax

A=vf^2/(2x)=7.9 m/s^2

Next find force

F=ma = 1890N

Using a torque balance find force at rear caliper:

R tire: 26.3/2=13.2in=.34m

R Rotor = 11.75/2=5.9in=.15m (minus half piston diameter = .135m

So tangential force at the caliper = 1890N*.34/.15 = 4284N

Using friction:

F=Ff/u=4284/.40=10710N

Now I’m going to convert to pressure (and imperial units because they’re familiar to me)

P = F/A = 10710/.0026 = 41.11E6 Pa = 600 psi

Using a master cylinder area to convert to linear force at master I get 220lbs,

Now I can set up my linkage according to how hard I want to press down to achieve this.

For 20 lbs of pedal pressure I need a roughly 10:1 mechanical advantage.

If I was using a ½” bore cylinder I could reduce that to about 5:1 (which is about what I would expect), but the whole reason I am using a pull type master is for good placement, and in order to get good placement, I need to make linkage, so I’ll simply tailor the linkage to my specs.

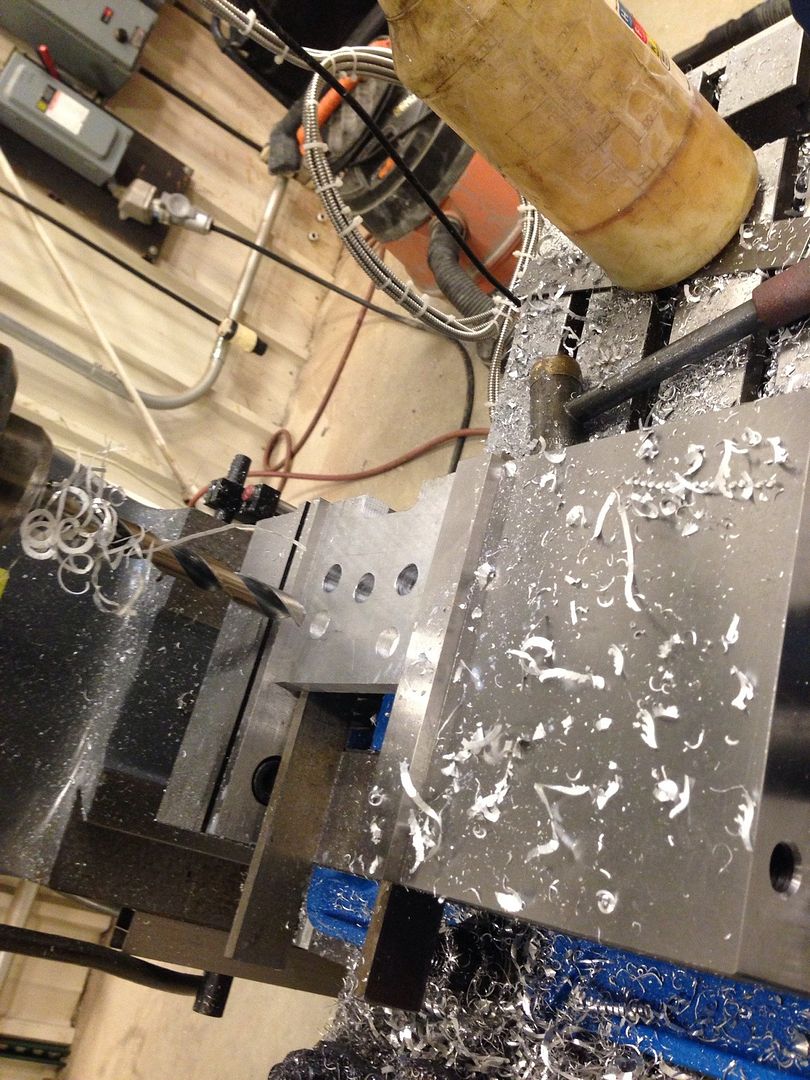

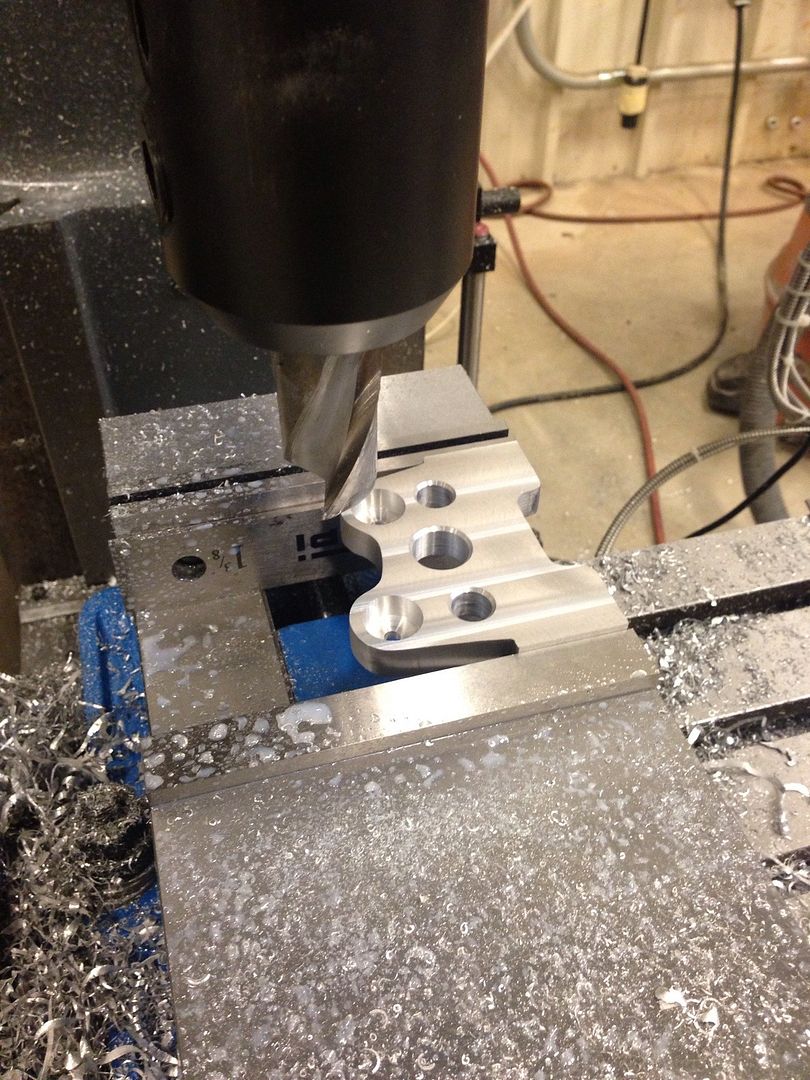

Oh, also, here’s a shot of the completed clutch system. Everything here (with the exception of the footpeg) was made by hand from scratch. No CNCs were used, just semi-basic tools.

(let me know if that pic doesn’t load)