I’d assume those comments also come from people without the talent or resources to accomplish the job anyhow. Shit man I don’t know you from anybody else here but every project you have put up is top notch. Def. impressed by the level of talent in these threads. Also when this is finished how do they decide the “winner”? Is it a vote based thing on the web?

If you are an actual engineer see my thread about needing to hire a design engineer. ![]()

http://www.nyspeed.com/showthread.php?239483-Testing-waters…-Fluid-power-design-engineer&highlight=Design+hydraulic

+1. I check this out everytime I sign on. It just doesn’t happen on the weekend.

I realize now it was on another form but, I can say that the amount of effort and skill needed to make some of these parts is at a level that most people will never comprehend. However, I think those that understand the process to make those parts frist off realize you can’t just design it up, machine it, and slap it on. I would say 80% (which is more like 99%) of the time during the prototype stage everything is modified. So why not just make it by hand…it’s actually less time cosuming in some cases (If you start off manually making the part the machine is already set to go to modify it…Imagine if you programmed your holes but ‘forgot’ those chamfers. We all forget something. You would have to manually add them anyways). You can never put to paper what will actually fit. Especially on one off pieces. You can never accurately measure every condition and you will never be happy with the first concept.

Those that make the snarky comments are either too stubborn to admit they are simply too dumb and do not understand what is going on. Or, they are simply jealous they can’t have something that rad.

Back to awesome bike build.

Most people don’t understand what it really takes. Sometimes its disheartening.

A lot of them weren’t in my thread but elsewhere on the board. IDK, maybe I’m just jaded for no reason.

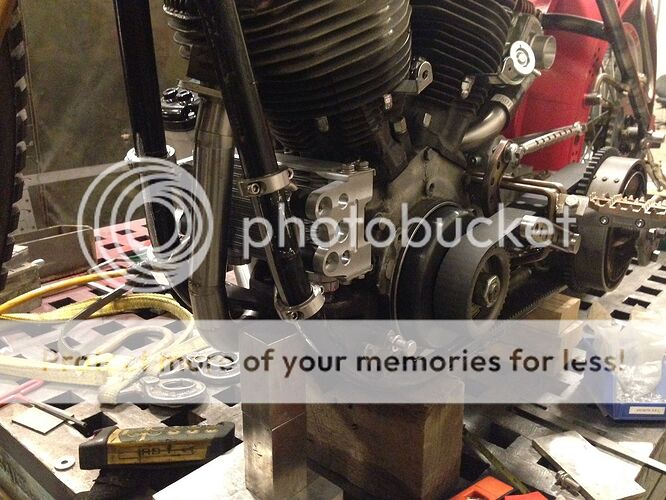

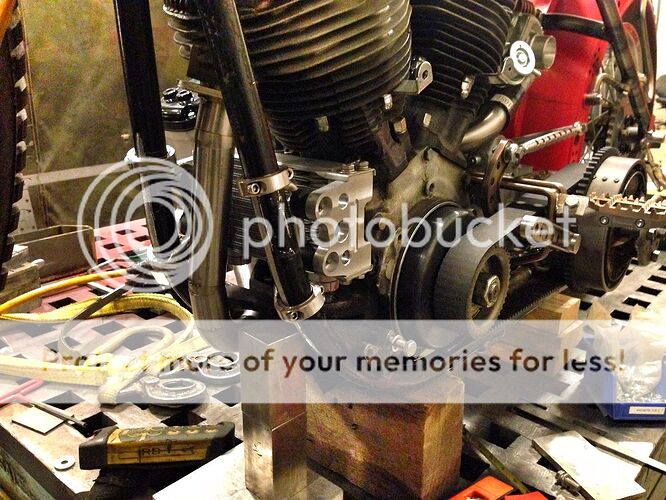

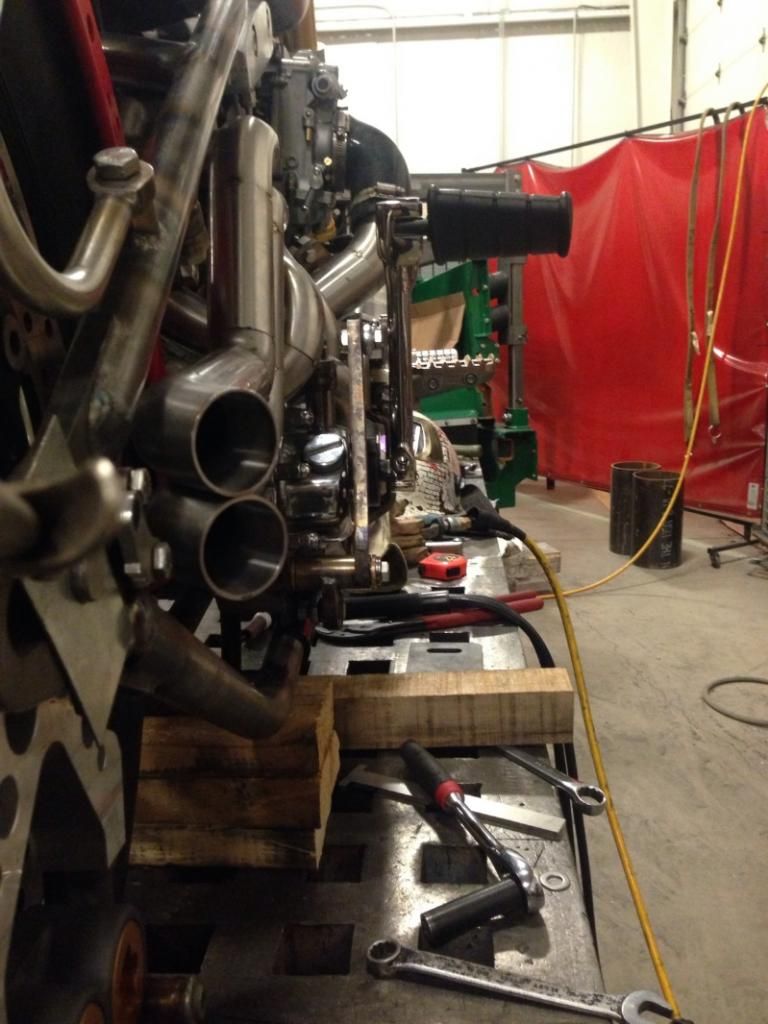

So this is the part of the build where I chose form over function. Well, maybe I’ve done that a lot.

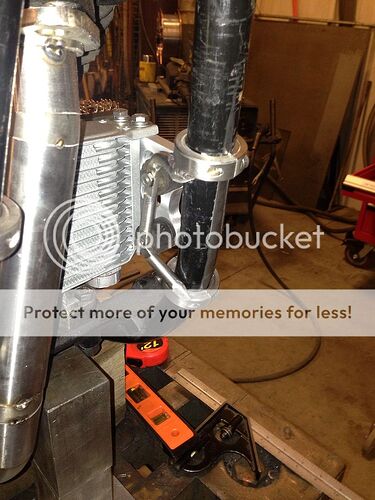

Anyway, I installed my oil cooler between my manifold and my engine case. As far as radiant heat goes it’s not a great place, but it’s better than NO oil cooler. It’s hard to tell, but there is about 1" of space between the pipe and the cooler. I may squeeze a small heat shield in there, or perhaps ceramic coat the pipes once I’m sure they’re dialed.

Some pictures:

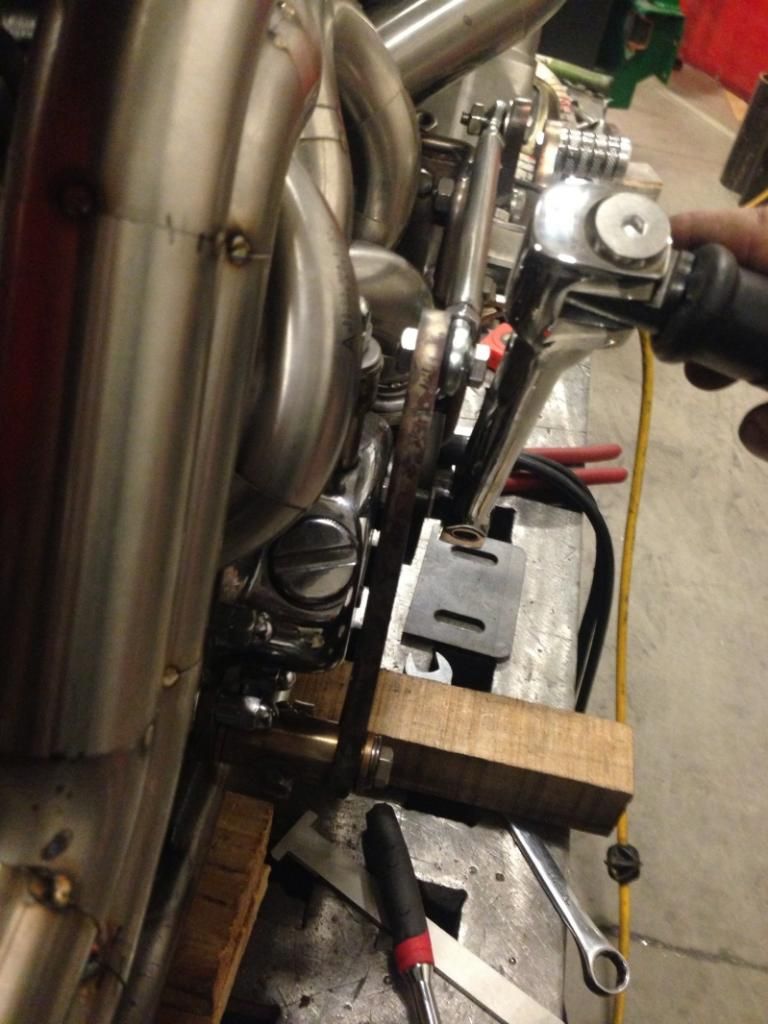

Also the first time I’ve polished any of my welds. There was just so much “silver” in this area that I decided to get rid of the burnt/welded SS look here:

I later sanded these smooth and polished off the color:

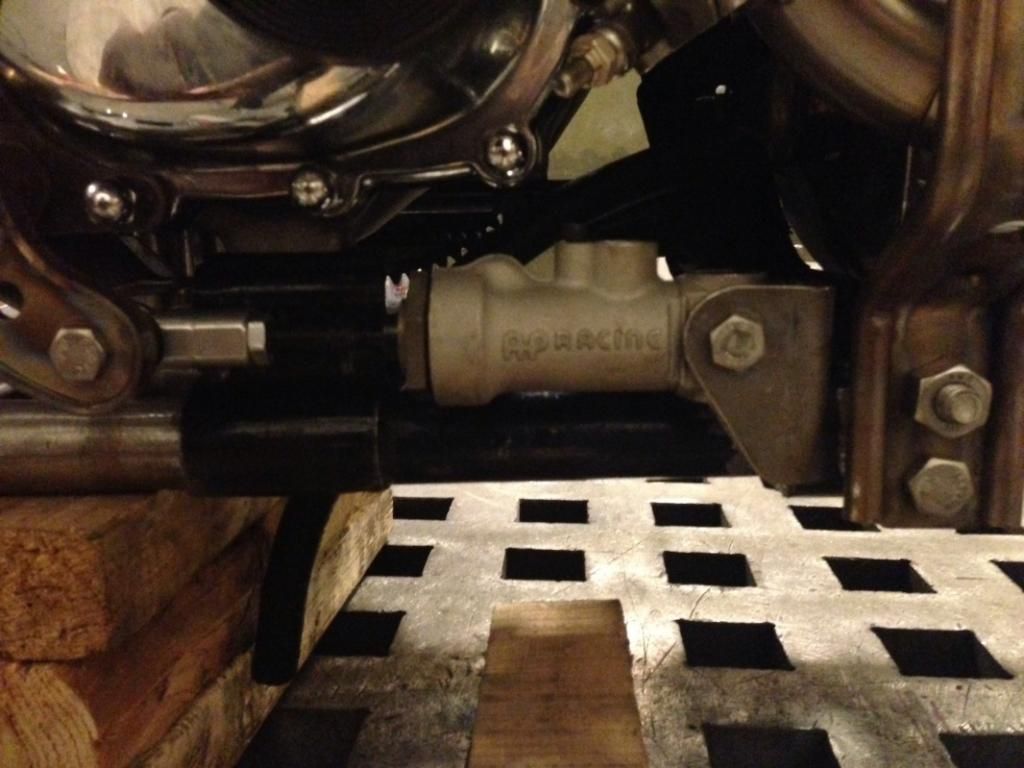

I also scooped up this pretty rad used AP racing pull-type master cylinder. You can get them used for about 70 bucks, but new they are nearly 500! WTF. Tonight I hope to get most of the brake linkage done.

I have to say that it’s most likley just jealousy of the access you have to better tooling and equipment…most “DIYers” are working out of their little 1-car garage at home and are lucky to have things like a drillpress and chopsaw, which are major limiting factors in what you can actually make without getting really creative. Having the monstor welding table to use for a build table, the bridgeport, 3D printer all at your disposal is nothing short of AWESOME. I have no problem admitting that I am just plain jealous that you have access to that sort of equipment to really find the extent of your capabilities. I’d love a chance to enjoy the same previlage but I don’t work somewhere that has anything like that. Shit, I’m fighting my ass off just to get a large-format copier/scanner and a survey gun.

$500?!? Everyday I am more and more convinced I am in the wrong business. lol

Can you tell me what the dims are of just the cooler itself? 10"x4"?

It’s way smaller. The core is only like 5x4 and overall it’s 8.25x4.

It’s an earl’s 21308ERL, they have a million. I also have this setrab one that I would sell. Never used, silver.

http://jagg.com/images/universal%20coolers/Univ%20core%20drawings/3140.pdf

---------- Post added at 01:27 PM ---------- Previous post was at 01:26 PM ----------

All AP racing shit is retardedly expensive.

Not to high jack. I’m just looking for one for a air cooled 250cc quad that im building. I’ll probably pick one off of a 400ex off ebay for $30. Room is limited for me also, but your pics give me reference for size.

Thanks.

Well put.

Good ole Earl.

While it’s a decent chunk of change, you can buy a bridgeport in good shape for under 5000, and a nice tig is 1500.

I need to get a TIG badly. It’s my main limiting factor when working on my projects. That and $ lol

see you this weekend fruitcake

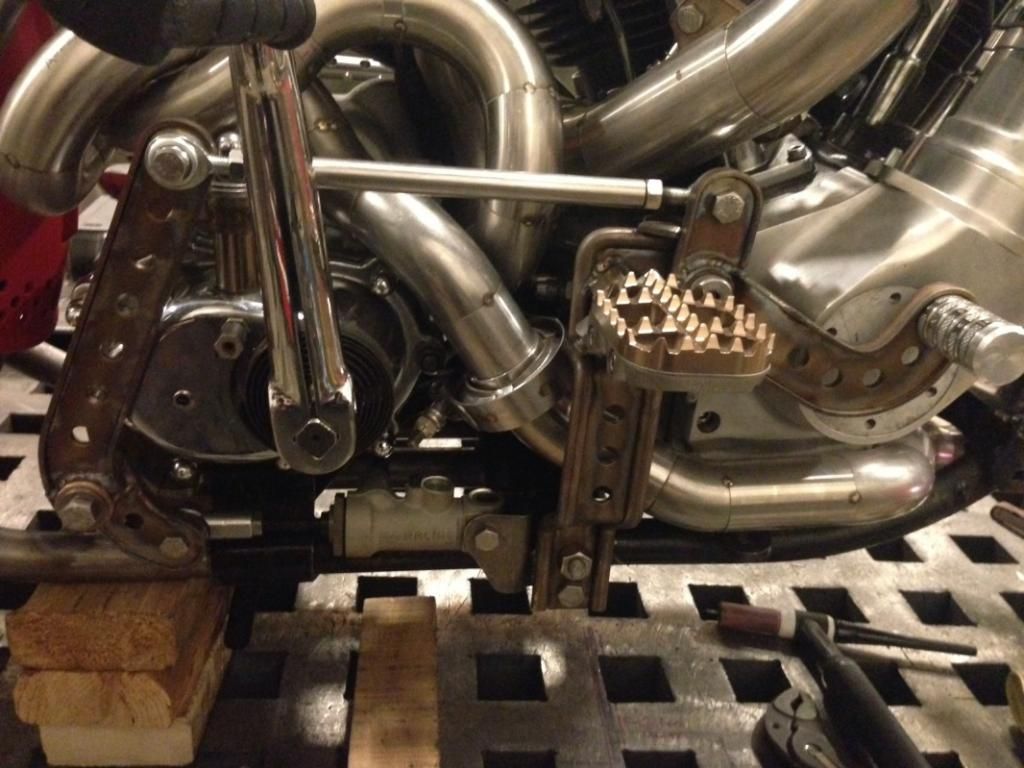

Finished my brake linkage (minus return spring. As mentioned earlier there is a reason everything is the length that it is.

This is how I made the linkage pieces:

Making a MC bracket:

About 20 hours later (seriously). Everything here with the exception of the rod ends and master cyl are handmade without any special tools.

Perfect:

Brighter:

This bracket picks up two kicker cover bolts and the right side mounting bolt. The first one I made was a 1/2" shaft and only used the kicker cover bolts. I was worried it would flex so I built this one from 1/4 304 SS and punched the rod right through it and tied it to the heavy plate that bolts underneath the mount on the frame.

Another shot. I guess I should clean it up a bit but you’ll never see it… It’s the details that count, though.

The master cyl:

Brake arm with stop, peg, etc. If you missed it last time the flair on the brake peg is a bunch of men’s rings I ordered off ebay. Titanium and carbon fiber, complete with a cubic zirconia.

And here’s a shot of the bike as it sits right now:

Going to be slow on the updates for about 2 weeks.

plans for the front radial caliper post mounts?

Rad.

Oh and this

=

Very cool. Looks like you could use the other holes in the MC arm to tweak the leverage if need be.

Dan