I think all of us do…especially on the tools part. As for time…you either have to have a very supportive understanding g/f, or a series of not-understanding ones. I haven’t nailed down which of those options I’m currently dealing with, but it’s definitely one of the two. LOL

lol, so true.

looks good brother. im going to fabricate a motorcycle mount for the dyno tomorrow. I also have my lm2 for datalogging and shit when your ready. :tup:

So I’m assuming that they belt doesn’t do anything too important, i.e. timing belt. (if it breaks, it’s just a simple replacement of the belt, nothing internal)

It connects the motor to the trans.

I think he means other than the belt hurting you physically, or it stopping forward progress no damage will happen if it comes off.

I know. I just thought explaining what it did would answer that.

Give me some credit, guy.

:tup: got it.

Kickstand time!

Cad action:

Fabbed (half by hand, half laser from 304SS):

Mounted it:

Put a spring on it that’s sorta hard to see as well as a little peg to put it down:

Then I realized I sorta fucked up and had it leaned over too far:

So I had to cut the mount off and reweld it on there. It was originally at 20 degrees which looked sorta rad but was just too aggressive, so I brought it up to 14 degrees, which still is very stable even w/ a 2x4 under it so it should work well in the “real world”:

Then I also made these “highway pegs” to give my legs a break if I start getting tired. They’re pretty short, but enough to get a heel on on the mag side and the whole foot on the drive side. Worst case they’ll also act as frame sliders.  They are identical in construction to my Honda’s pegs that I made.

They are identical in construction to my Honda’s pegs that I made.

14 degrees looks better… and safer. At 20 it almost looks unintentional as if the stand bent under the weight of the bike.

Yea, I’m trying to figure out what to do for the kickstand on my KTM. it was too long with the 17s on it and broke when I tried to bend it. haha. I might just sleeve the two sections together so I can put in a longer sleeve when dirt tires go on occasionally.

Made an oil filter relocater bracket (mild steel) and a license plate mount (stainless) tonight all from scratch.

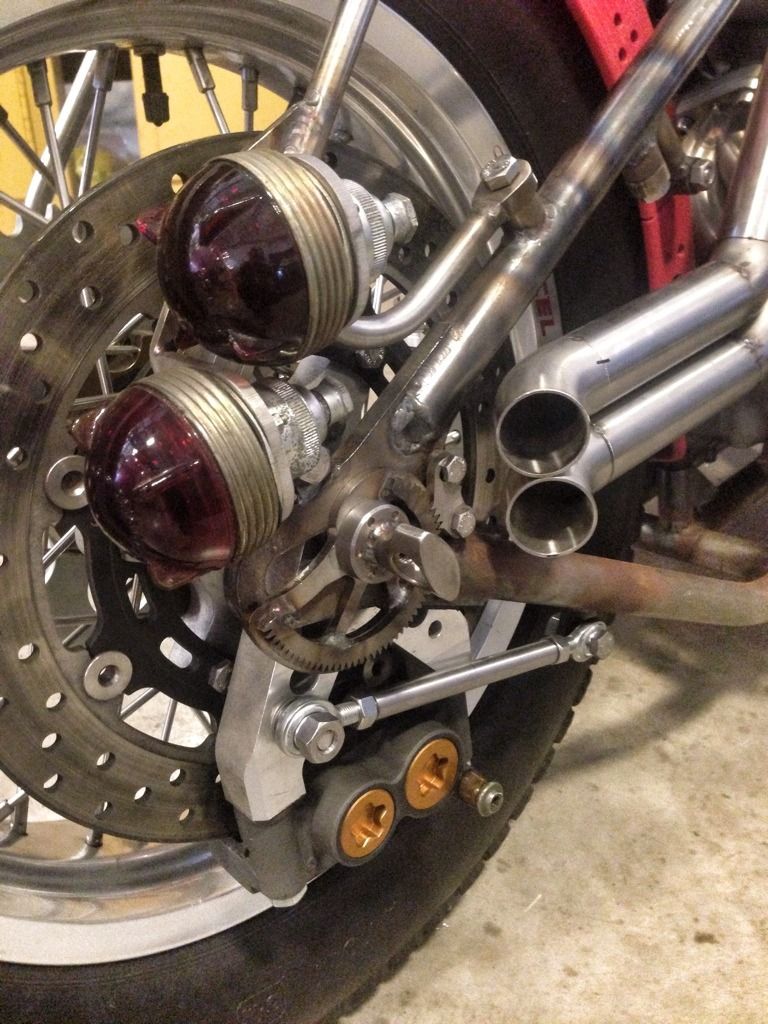

Finally made a rear axle and was able to get rid of those stupid plates I had vice-gripped on there to hold the wheel.

Threaded a piece of 3/4 round, machined a gnarly bevel into a mating cap, welded it to the shaft, machined the end smooth and then welded on this weird thumb screw I found to allow me to tighten it. (the nut is on the opposite side if you are confused) Also cool to see my tensioners I designed in action:

I like that!

So I welded up the downpipe so I could weld tabs onto them to mount to the frame. I think I am changing my clamp idea and it wasn’t NECESSARY to weld up but it came out pretty good. I made some temporary jigs to hold the pipes and they worked really well.

Hopefully tonight I can make the clamp.

So I decided I was going to make the exhaust clamp tonight. I had planned on modifying some shaft collars. Here’s what I did:

Took some collars:

Machined flats into them:

When that was done:

I welded them together:

But then once I installed it I decided I didn’t really like it. I think it broke up the flow of the exhaust too much.

So then I started over with some new ideas. Here’s a pretty detailed series of pictures describing the process:

Good lookin’ stuff for sure

Definitely better 2nd time around.

THIS. Those are tied into the bike WAY cleaner than the clamp idea. This thing is really shaping up pretty awesome. I also have to say I was pretty happy to see that you made the mounts on a drillpress and band saw vs. a fancier way.

I also have to comment that I might feel really disappointed to see this bike all prettied up with paint and PC…I think the fabrication and means of building it should be showcased more. It would also be hilarious to park my bike next to yours because mine is such a piece of shit thrown together in a garage and yours is all systematically built with precision and engineering haha…but then again parking them next to each other might also be insulting to your bike lol

Man, it’s almost like you know what you’re doing… :poke: for real though, I just want to see this thing with paint on it.