newman

June 21, 2013, 6:45am

541

focusinprogress:

THIS. Those are tied into the bike WAY cleaner than the clamp idea. This thing is really shaping up pretty awesome. I also have to say I was pretty happy to see that you made the mounts on a drillpress and band saw vs. a fancier way.

I also have to comment that I might feel really disappointed to see this bike all prettied up with paint and PC…I think the fabrication and means of building it should be showcased more. It would also be hilarious to park my bike next to yours because mine is such a piece of shit thrown together in a garage and yours is all systematically built with precision and engineering haha…but then again parking them next to each other might also be insulting to your bike lol

Well it’s not going to be TOO prettied up. The only thing getting painted is the frame and fender/tank. All the parts I’ve made are stainless and they’re staying exactly as they are. Burned and brown.

Like my e30 is. Finished but still somehow super grimy.

hopefully this will get driven more than the e30

newman

June 26, 2013, 6:23am

544

This is why I’m behind schedule. Spent several hours making a fancy stainless voltage regulator bracket that no one will ever see once installed.

I also pulled the motor last night to start rebuilding.

seems kind of thick to just hold a voltage regulator?

side note: punched holes are sweet.

newman

June 26, 2013, 6:59am

546

It’s 7ga. I am sure I could have made it from 10ga and saved .006 lbs but I had the 7ga available. It’s also on quite a cantilever so the thickness isn’t hurting me.

Yeah I like punched holes too, but straightening the material out afterwards can get annoying.

newman

June 26, 2013, 8:02am

549

L8APEX1:

Stock motor rebuild ?

74" to 80" (3-31/32 stroke x 3.4375 bore to 4.25 x 3.5)

T&O Forged crank

Debating on stock cam vs Andrews 1 grind and if I should switch to solid lifters.

who’s doing your engine machine work?

newman:

It’s 7ga. I am sure I could have made it from 10ga and saved .006 lbs but I had the 7ga available. It’s also on quite a cantilever so the thickness isn’t hurting me.

Yeah I like punched holes too, but straightening the material out afterwards can get annoying.

Yea, I guess it’s going to vibrate a little bit.

But the turbo doesn’t go inside the motor…

I’m researching a similar project.

newman

June 26, 2013, 10:07am

553

The only machine work it needs is a bore job. Probably klispie’s.

nice. I’m planning to go to O&L as he’s super familiar with motorcycle builds cause he does all the machine work for Big Ed’s and Empire Cycle.

newman

June 27, 2013, 10:18am

555

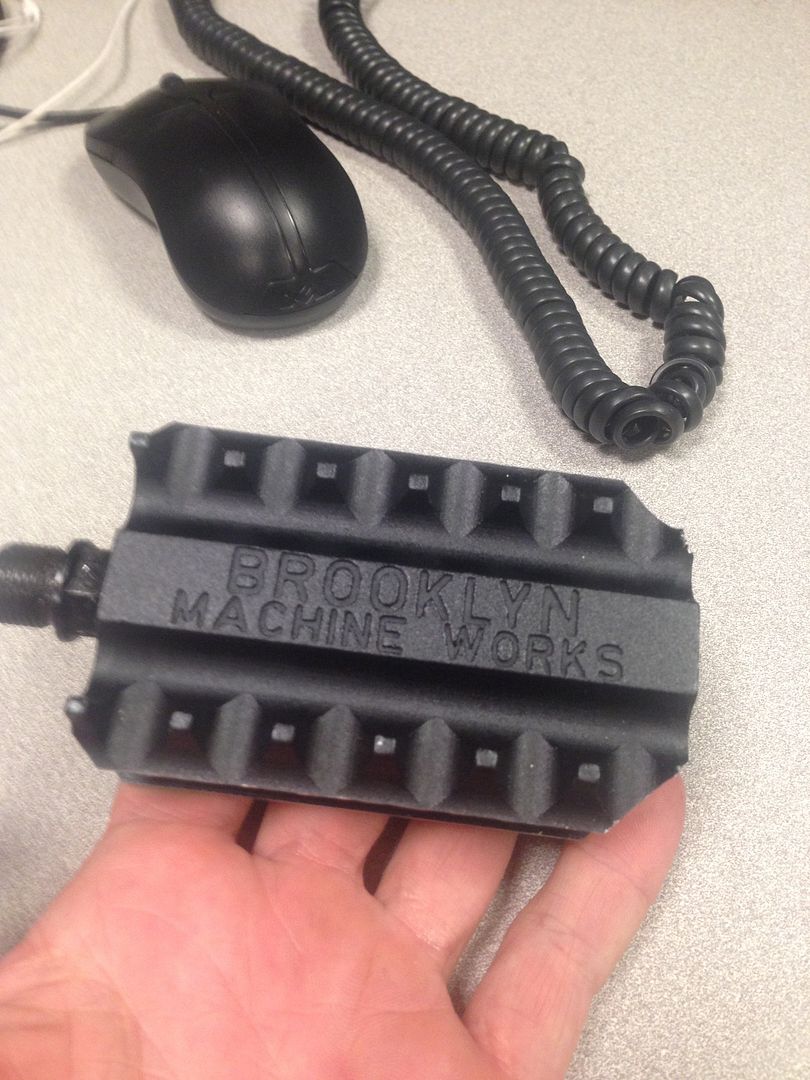

After much searching, scored a set of these rare, discontinued bike pedals (made right here in NY) for a pretty penny.

Obviously it’s too big, so cad and cutting:

Now it’s about the size of a factory kicker pedal. Still have to make or modify the spindle.

Meanwhile people in the bike community are freaking out… sorta like when you cut up the Mtech bumper cover.

Dan

newman

June 27, 2013, 10:23am

557

That was exactly my thought.

haha yea I cringed a bit when I saw it in the mill

sobo

June 27, 2013, 10:34am

559

I love when you cut up rare things.

I think modifying (or completely changing / repurposing) “rare” automotive things like this should be your niche. Like people who take WWII plane parts and turn them into furniture, etc.