Hell yes! Lets see some more of this mother.

Update as of this weekend.

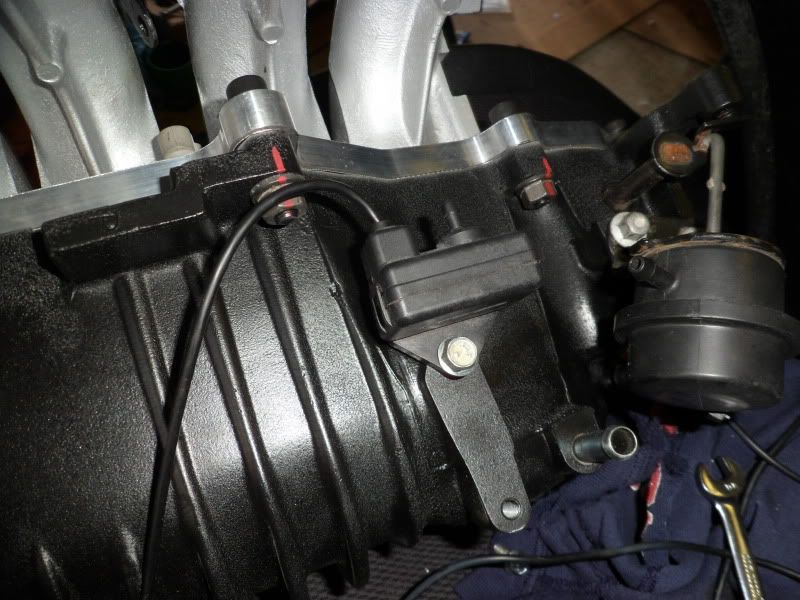

Drilled and tapped acouple of the casting nubs on the mani for adel clamps

Everything bolted together finally

Defi boost sensor mounted

Made a new starter wire so I could tuck it nicley along the lower rail

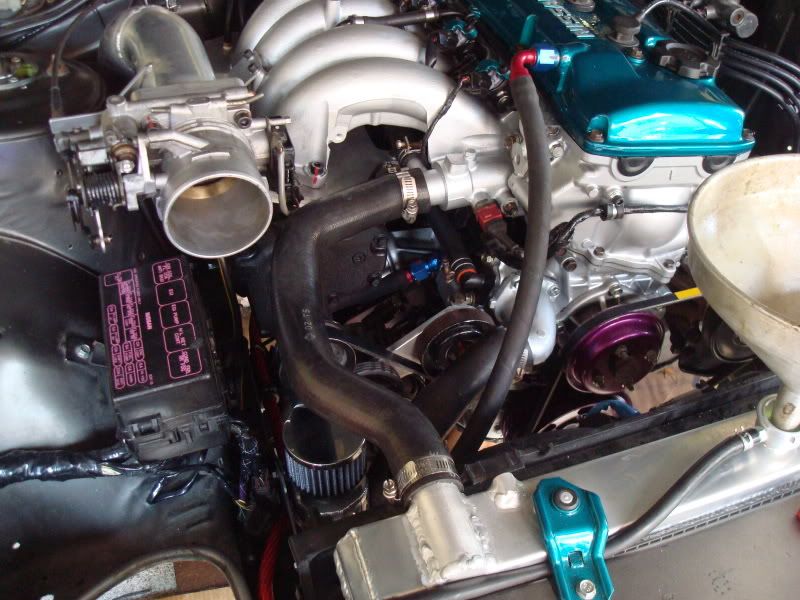

Got the supercharger and mani bolted up, heater hoses and fuel lines run.

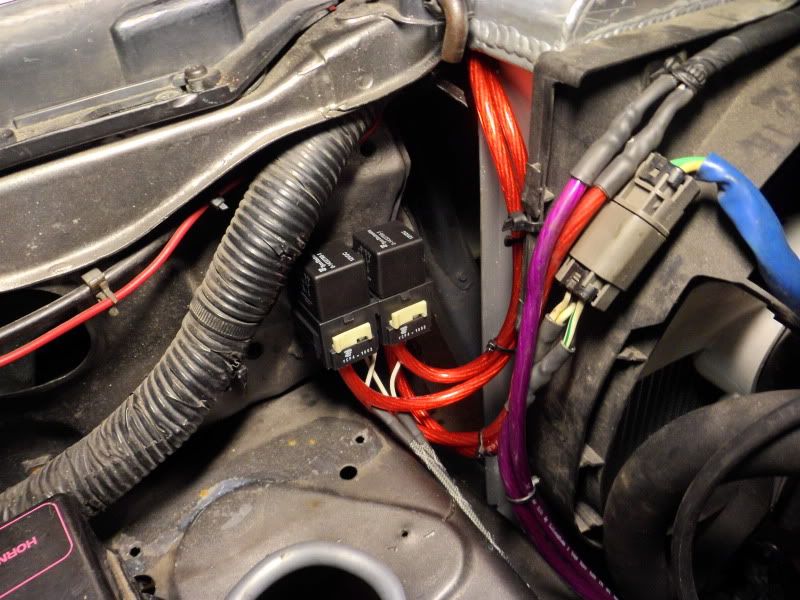

Ordered some gangster TE connections Milspec relays, sockets and terminals for my e-fans. These things are real nice and the sockets make keeping the wiring clean easy. I know the 8 gauge is overkill, but w/e.

Peak performance race tranny mount

Got all the Defi sensors installed and wiring run, gauges installed and wired.

Started working on a ghetto coolant overflow. Castrol represent.

Intake parts. 6" bellmouth velocity stack, 6" air filter, 3.5" piping, t-bolts and couplers.

Wiring harness installed, and supercharger inlet and intake installed temporarily. This is how I left off Sunday.

Waiting on my alternator relocation bracket from the machine shop, then all that needs to be done is rad hoses, themostat hosuing, belts and final installation of the intake. Then tune time, finally.

i have mad respect for your build man, inspiration for mine!

holy shit! crazy build man! Not a fan of the belt angle for the alt> i see “traction” issues with that.

looks very clean and propper +1

Haha, hurry up and get that LS going. I’ll be back soon to motivate

From what I’ve read you need a minimum of 30% wrap around the alt pulley (108 degrees), I’ve got roughly 140 degrees or so. So technically I should be fine, we’ll see though.

Thanks man!

lookin good trev, question tho, are you gonna be running an intercooler?

^ nope, no intercooler. When I’m done school and have an income again I’ll probably install water/meth injection and maybe get a quick change pulley kit so I can run more boost.

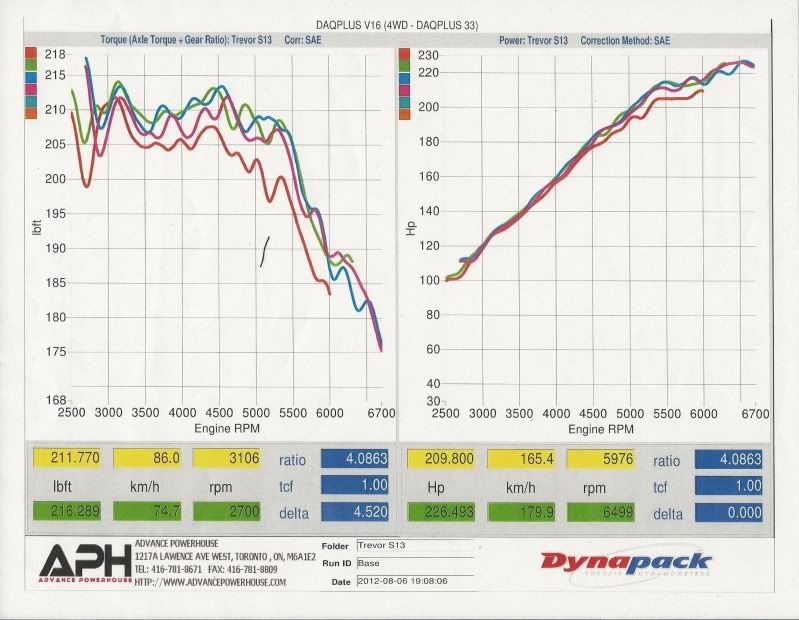

Well it’s been a busy few weeks for me finishing up school and making sure I had the car running and tuned in time to write my final tech. report. I was home acouple weekends ago and got the car finished up and managed to get it to idle. Next day got the car towed to APH and had Sasha tune it, huge thanks to him for fitting me into his schedule. We came across a few problems unrelated to the supercharger kit itself on the dyno but still managed to get it tuned to a decent point.

Heres where I left the build:

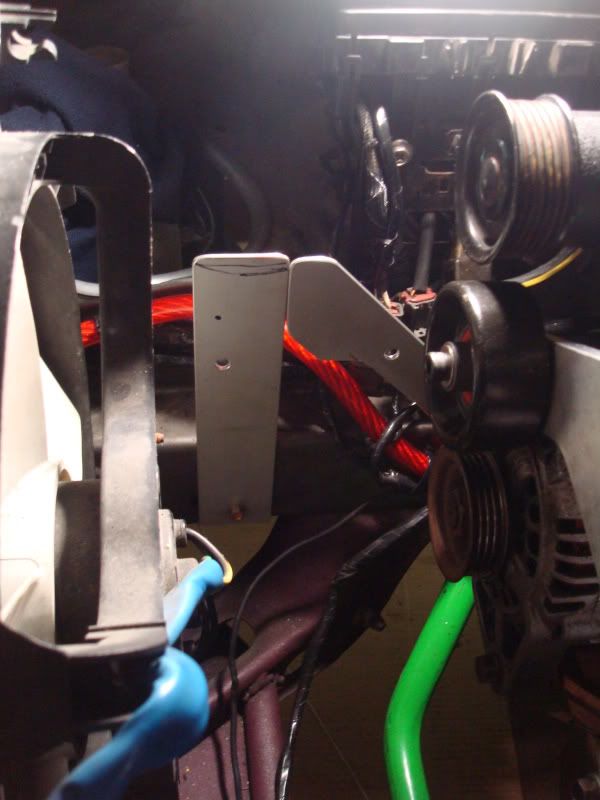

Got the alternator bracket back from the machine shop the second time. It was still shitty, but good enough that I could use it.

Bolted it up and got the pulley’s on

Started mounting up and running the lines for my catch can. Allstar performance baffled catch can, very nice piece and great for the price.

Called every auto parts store that I could think of in my area and finally tracked down the right size belt I needed. Think the belt size ended up being 76.4" or something. Here’s the belt on and tensioned up.

And catch can lines run, rad hoses on and such

Got the car to idle after some messing around and learning the AEM software. Next day while doing some pre-dyno tuning with Sasha, the power steering high pressure blew out of nowhere. Great. Huge mess everywhere, and the possibility of ruining or even seizing the pump if we ran it on the dyno. Tried to get a belt the right size to exclude the ps pump from the belt system but couldn’t find one at the local CT. Said fuck it and just ran the car. Burnt the pump pretty bad, but not a big deal to replace. I wanted to put a non-hicas pump in there anyways.

Had some overheating issues with the car when we were nearing the end of the tuning, so we wrapped it up abit early but got acouple good power pulls in before then. Haven’t had time to diagnose the overheating, I’m hoping its just an improperly bled cooling system and not a head gasket… Anyways here’s a short video I made for my tech project

Good work man, you did it.

Project Do Work is complete

Awesome! A pretty nice little Wednesday morning read with my coffee haha. You may have mentioned it but how will this setup do with emissions? Or is it not going to be used for street?

Also, not that it’s any of my business but could you outline the scope of your tech project? What was the goal of your report?

I don’t know why APH’s power delivery is so sporadic… this is the 2nd tune that i’ve seen from them with such a blimpy powerband…

Haha, not a chance. Already have a list of stuff to do next, it’ll never be done.

Glad you enjoyed it. I made the setup to delete all emissions equipment, “for track use only” purposes. That being said it will be my DD.

Here’s a quick copy and paste from my report.

Purpose

The purpose of this report was to make a kit able to adapt an Eaton M62 Supercharger; factory equipment on the supercharged 2002-2004 Nissan Xterra and 2001-2004 Nissan Frontier, onto a 1991-1994 Nissan 240sx equipped with the factory KA24DE engine.

Scope

This report covered the steps of engineering, producing and installing the necessary parts and modifications to adapt the M62 supercharger onto the authors 1993 Nissan 240sx. Due to time and knowledge constraints, this report did not include the programming logic or concepts used to tune the engine control unit (ECU) necessary for the vehicle to run and function properly.

Really its just the scaling of the graph they have it setup for. The torque graph has a very narrow range which makes it look so sporadic.

Nice build

Nothing cool to update, just some b.s. talk

Turns out the head gasket decided to take a shit. So unfortunately not going to put the car on the road this year, just wouldn’t make sense at this point. I just picked up a first gen 4runner for a winter beater. needed something cool to tow my sled with.

ARP headstuds on the way, decided to go with a felpro gasket because of all the shit I hear about the cometics. Going to do a cam swap while its apart, not sure it i want to go with the 248/248 or 248/240. Anyone have any experience with either? A few small interior/exterior updates should be on the way soon.