Wedge a bar/heavy duty extension between the Crank counter weight and the bearing caps…you should be able to pop it off with an impact no problem. I would avoid using a breaker bar this way though.

Hmm… didn’t think of this one… might work; have to look to see if there’s any place to insert a bar. Can’t do much until Wed anyways (Impact wrench delivery, gotta love Amazon Prime!)

When I was torqueing my ARP crank bolt, I had no flexplate on the motor and no way to stop it from turning. I have an iron block which is much more forgiving, but I stuck a thick bolt into one of the recessed holes on the crank counterweight, and turned the motor until the bolt stopped against the inner block wall. It worked just fine. I actually ended up bending the bolt slightly, but it worked like a charm.

Update - Got my new Impact today (Aircat 1200k); and grabbed a new 3/8" air hose. 2 flywheel bolts from the dealer ($15 for to bolts, my ass hurts!); and a 3’ piece of 1/8" x 1.15 x 1.25 angle steel bar. And the Balancer came right out, maybe 3 “hits” of the impact.

Broke 2 Harbor Freight pullers getting the Balancer off though; sent bolt pieces flying everywhere! That was uhm, fun… But it eventually came off the 3rd time; doing the wrench, then whack with a 2# sledge a few times, then repeat.

Then the front cover, oil pump, timing chain, camshaft, rear cover; and the Main Caps. Bearings look damn good. I’ll grab some photos tomorrow and post them up. But so far it looks like the crank just needs a polish, and the block just needs a clean and hone. crossing fingers.

good to hear!

:tup:

Ok, well, got some more accomplished the last few days.

Motor is completely apart, block and crank are heading to the machine shop on Monday. Should have them back in a week. Crossing fingers that it’s just a wash/polish/hone job!

Rest of the pile of parts…

I’m thinking J&J was right about the oil changes… found a bunch of sludge behind the main bearings when I removed them from the block, and the insides of the front/rear covers are pretty discolored.

Got more done on the welding/grinding. PS is probably 50-75% done. Just need to do the grinding and touch up a few spots, then it’s onto filler. DS I got the fuse block bracket removed, and started prepping for welding.

Just got a call from the Machine Shop; block and crank are in good shape.

Just need a polish on the crank.

Block is getting the cylinders honed, and the deck milled .005 (just to get rid of some minor pitting on the deck surface).

Should have the block/crank back middle of next week.

Time to order some goodies to put the lower end back together.

And an update on the rest:

Pulled the fenders off the other night, got the fuel/brake lines removed (Both are getting replaced).

Started pulling apart things to send off to powdercoat and/or prep for paint. Got the Valvecovers pulled apart, started on the ACC brackets.

Started welding the DS up; so much easier now to run a nice bead then when I started, amazing how practice does help!

Need to order the new Radiator soon, so I can start getting that mounting fabbed up.

Nice!

This is the stuff I will need help with when I get around to it on an S-10 build.

I maybe back in B’Lo by that point… We’ll see what happens in 13 months…

Update -

Picking up the Block/Crank today. Took longer than expected, race season is starting up out here and they got buried; as mine’s not a “regular customer race motor” and I told them it wasn’t a rush job it took longer than expected.

Started cleaning up the parts that are getting reused, and getting other parts ready to head off to Detective Coating. Front and rear engine covers cleaned up nicely, as well as the windage tray. Have the Oil pan soaking currently.

Need to measure the Block and Crank to verify everything; then order the appropriate Bearings/Rings.

Sweet! Get this thing ripping already

^ What he said

That’s the plan… but it’s going to be slow and steady progress; I’m 99% sure she won’t see the streets this year; but the plan is to make significant progress on her.

As supportive as my wife is; the car comes last on the list of priorities for my $$ and time. Family, Work, School, and paying down debt all come first. I mean my wife is telling me to get it together and spend what I need to; but providing a sound household for her and my son comes first.

One awesome thing; my wife just got a new job, 1/4 the commute distance, and 50% pay raise… which means I’ll have more $$ to spend on go-fast parts while still reducing our debt load! ![]() Now the balancing act is going to be time more than anything…

Now the balancing act is going to be time more than anything…

:tup: priorities

Ok, figured it was time for a quick update. I’ll post what pictures I have later…

Got the Block/Crank back from the machine shop, both look awesome. Should be ordering tools and parts shortly (had some other things come up).

Did realize that I’m a complete dumbass with the block though… I used the wrong bolts when I had it bolted the stand for dis-assembly, and stripped/fucked up the threads on a few of the bell-housing holes. :tdown: But… that’s what they make Heli-Coils for. So those are order along with the proper drill bit.

Been making slow and steady progress on getting parts ready to send to Detective. GM’s casting department leaves plenty to be desired… Files and a Dremel tool have gotten a lot of work, and I’ve only gotten the Front/Rear Covers done and the Oil Pan about 90% done. Still have all the Acc brackets and Valve Covers to do still.

Question for everyone… How The Fuck do I get the carbon buildup off the inside of the intake manifold? I’ve had it soaking in a solution of 1/5 Power Purple/Water for a week now and it’s barely made a dent. The manifold looks great, other than the carbon buildup…

I found that brake parts cleaner will demolish any grease or buildup in its way. I spent hours cleaning the tops of my pistons with purple power and a rag, and just for shits and giggles on the last one, gave it a try with brakleen. The buildup nearly wiped away completely on the first pass. This was on aluminum pistons though, it may react differently on plastic.

Wow, moving along really well, when do you think you’ll have her back together?

Probably not till next summer. Have soooo much else going on with life right now; I only get a couple hours a week in the garage, if I’m lucky. Family, Work, and School are kicking my ass.

Ok, well, I know this is a slow and steady marathon of a project, figured I have a little time and made some slow/steady progress on things, it was time for an update with pictures.

Most of my time lately has been cleaning and prep work… Block, crank, covers, accessories, pistons, etc.

Getting the castings from GM cleaned up SUCKED/SUCKS… I’ve gone through I don’t know how many Dremel Sanding Drums and Cartridge Rolls. But I can finally see a light at the end of the tunnel!

Accessories getting prepped to send to Detective:

The steadily growing pile…

I don’t have any before shots (my bad); but here’s a bunch of afters; all the shiny parts are where the parts were sanded/filed/etc to remove casting flash, blend a casting seam mis-match, or clean up a damaged area. But these are the little details that make the difference in a build.

These parts I have probably 20-40 hours of work into. Most of that time being on the Oil Pan… that was fucking awful for flash and mismatch.

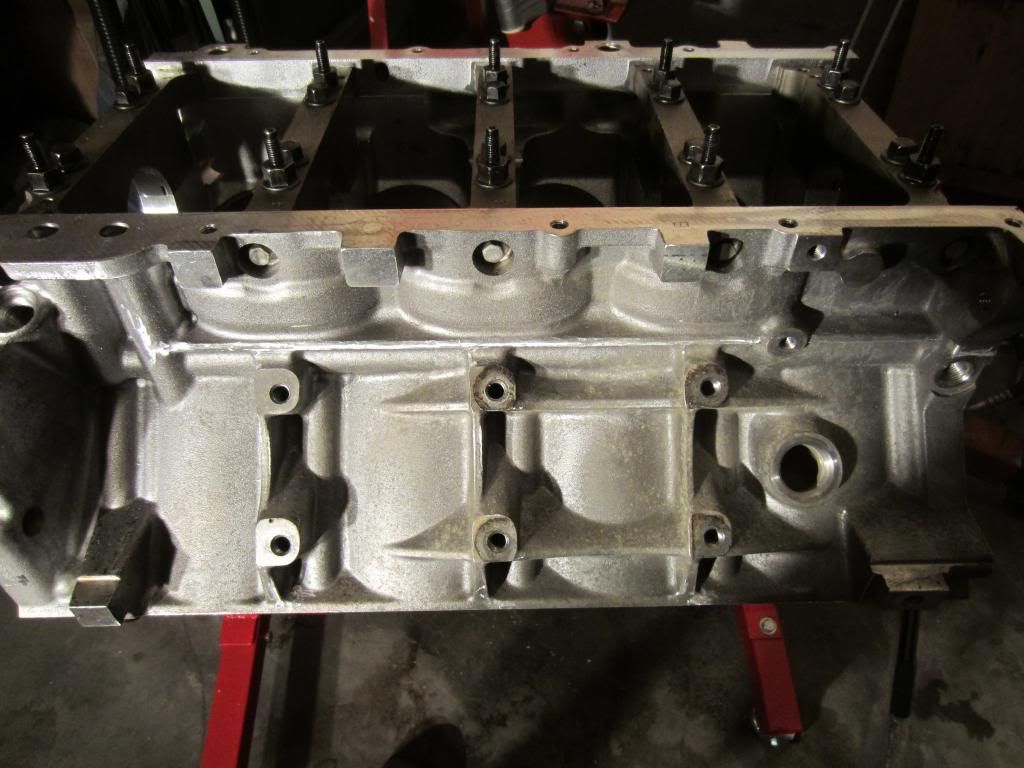

The block back from the shop. All decked. Got the Bell-housing holes heli-coiled without a problem, and the block onto a new stand (my old was a 3-wheel, and liked to tip over).

Then on to cleaning the flash and breaking all the sharp edges on that… fun fun.

Also opening up the oil drain-back areas; those were unbelievably full of casting flash, I mean horrid! Now they’re open wide and nice and smooth.

Pistons 95% cleaned up; soaked and scrubbed in gasoline, then a 48 hour soak in 25% Power Purple, then another scrub, now soaking in oil.

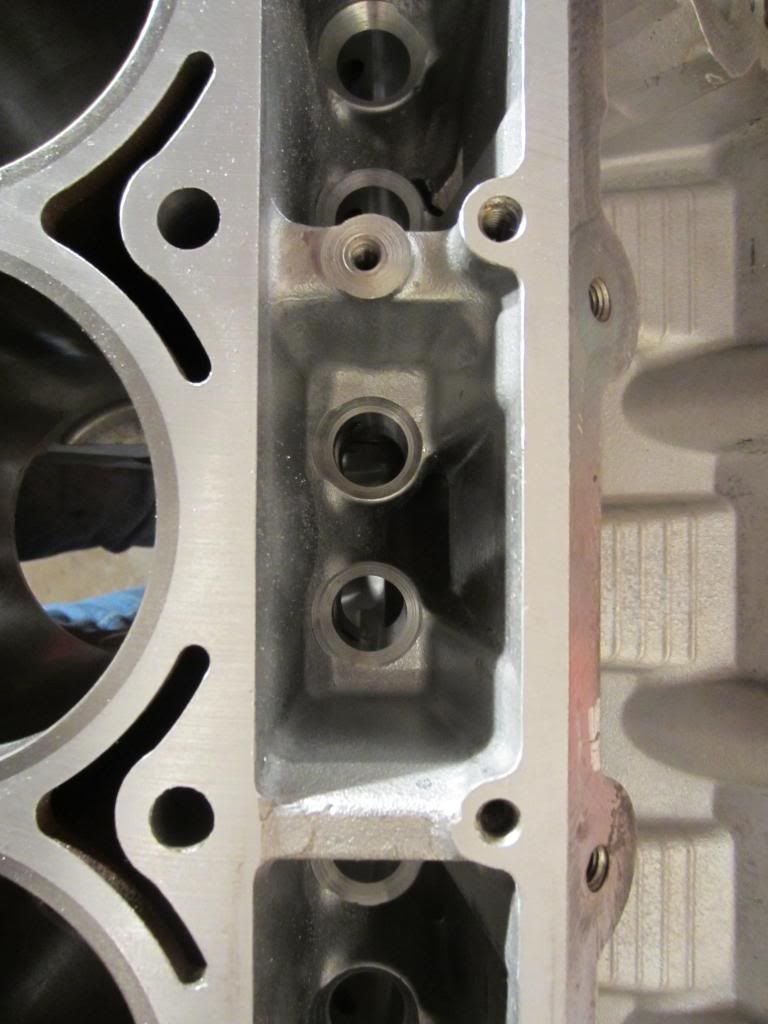

Cylinder heads; just starting to get these cleaned up. Have a disassembly Valve Organizer tray, and a valve spring compressor on order. Already have the Dikem, burrs, and Cartridge Rolls for the Home P&P Job.

New K-Member, un-packaged, and hung on the wall… I still don’t know if they’ve released this yet… all I know is it should work awesome for both this motor and the motor to follow… this thing will clear a 5" downpipe on both sides (due to the bent tubes and pedestal style motor mounts.

Welds are starting to look better! Have made jack shit for progress on the engine bay… Engine itself I’ve been concentrating on. Plus now I’ve got to balance the Air Compressor & Welder with the AC… the power feed to this house is uhm… insufficient for my needs.

Slow and steady… slower than I wanted… but that’s life. Should have the Block Cleaning brushes, Valve Organizer Tray, and Valve Spring Compressor here on Wed; so more progress on the block and heads should be made next. Pull the heads apart and clean those up and do a basic P&P job. And get the block pressure washed, throw new Cam Bearings into it; and paint her up.