LOL @ “that’s temporary”

So, this bike has quite a history among friends already.

Where checko left off on the previous page is how he traded away the bike for a set of Ronal Turbo wheels for his mk2 GTi project.

He sold the GTi, and Daryl (who got this cb360) decided he didn’t want a cafe’d one so he offered to trade rolling chassis with @pirite for his.

story on that bike was luke’s uncle gave him the bike with a locked up motor…which we free’d and got running…he got a lot of checko’s take-offs to make it a ride-able bike and enjoyed a full season of riding before a valve let go.

Luke sat on the project all this time and checko took a mk3 jetta as partial trade on selling his mk5 rabbit. He offered luke to trade for the 360 project back and luke now has a winter-beater Jetta…

and Checko and I have gone hard on this project again to sell it upon completion for some shared profits. Best part is…through all the trades no-one re-titled it…so it’s still in checko’s name LOL.

So, let’s examine the parts list of thing’s we’re working with here:

-1976 cb360 frame, with custom subframe and converted to monoshock using ninja250 swinger and zx6r shock/linkage.

-1974 12k mile beautiful condition running motor and carbs

-luke’s blown up half disassembled cb360 motor for mockup

-cb500T front wheel, previous converted to a 19mm bearing/axle instead of stock 17mm

-cb750 rear wheel

-1995 zx9r complete front end

-some 90’s ducati front brake rotor

-cb350f supersport tank

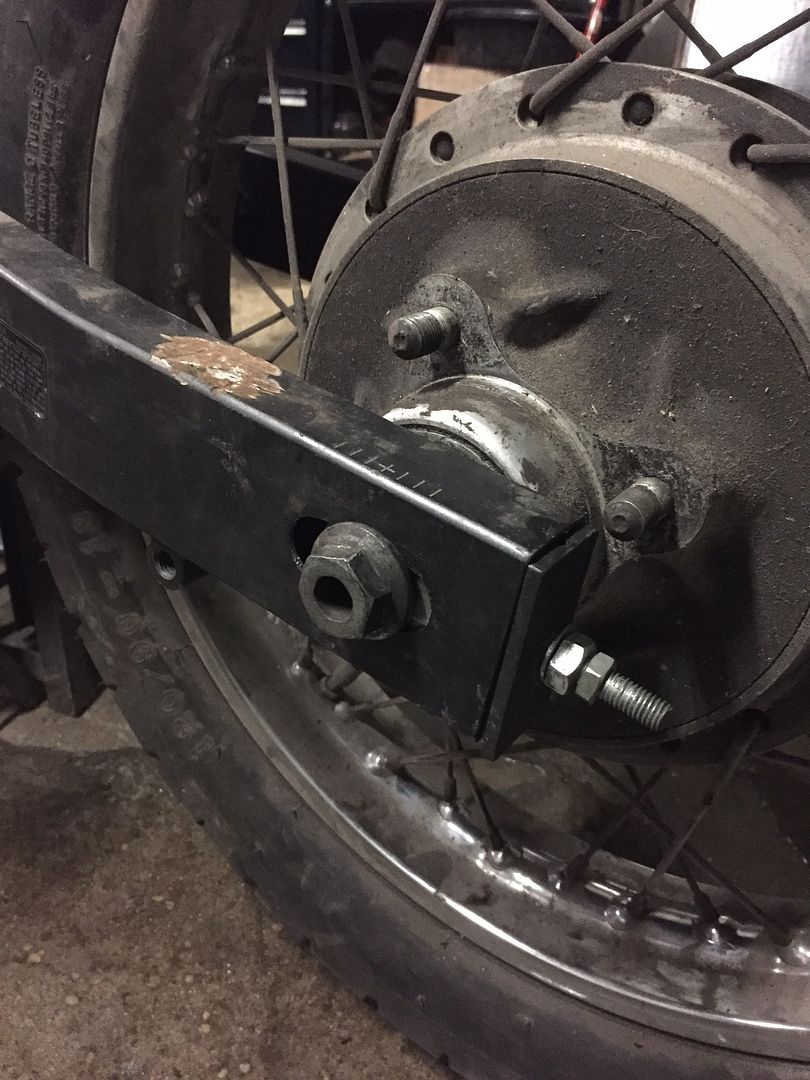

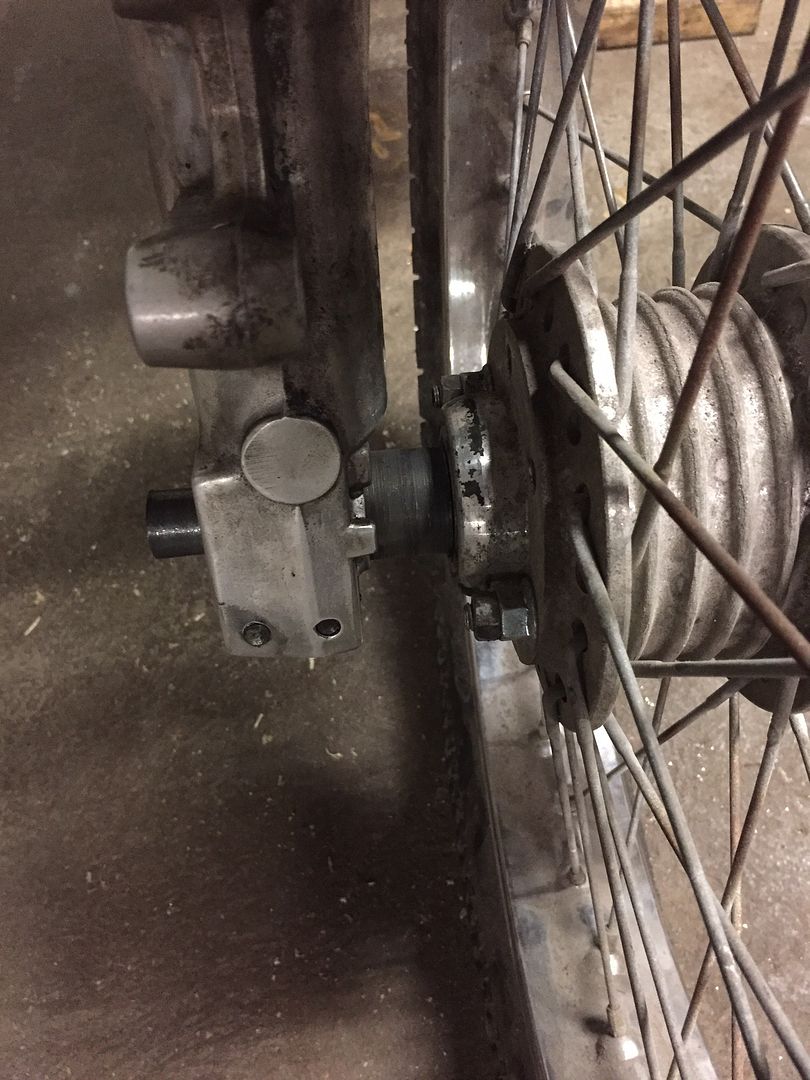

So, when checko last “owned” the bike, he’d never made it to working out the rear axle. the ninja250 actually uses a smaller diameter rear axle than a cb750, and the cb750 rear axle is too narrow for the arm.

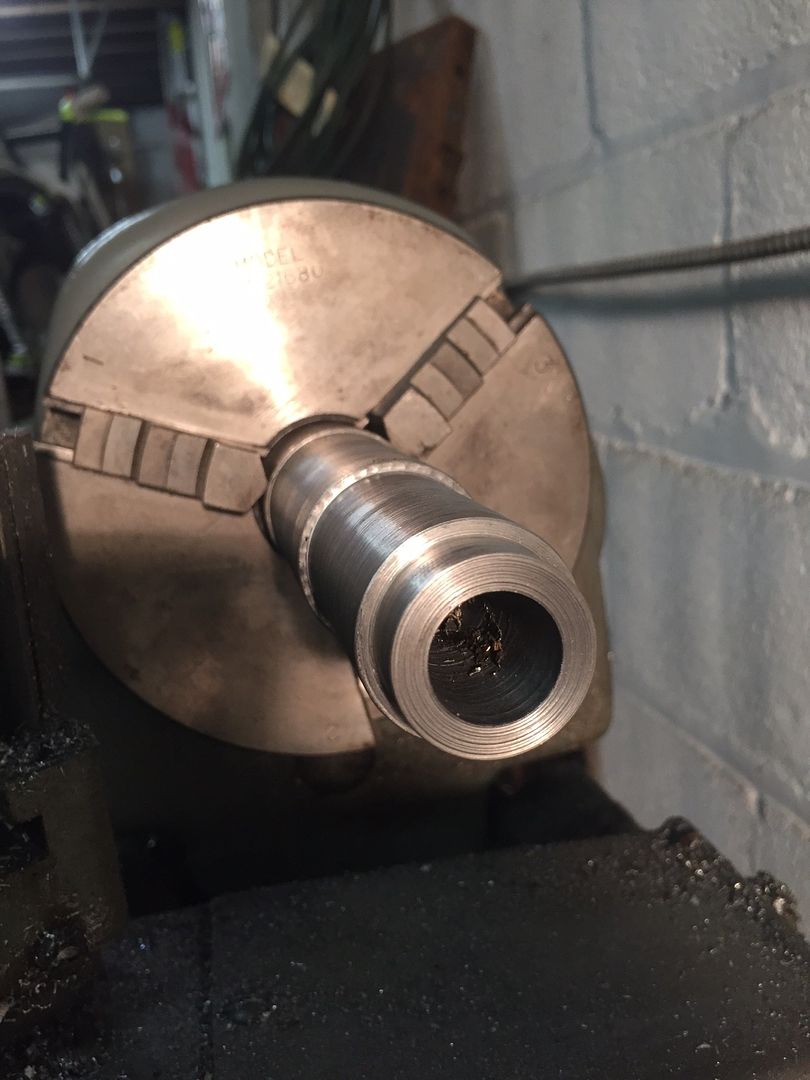

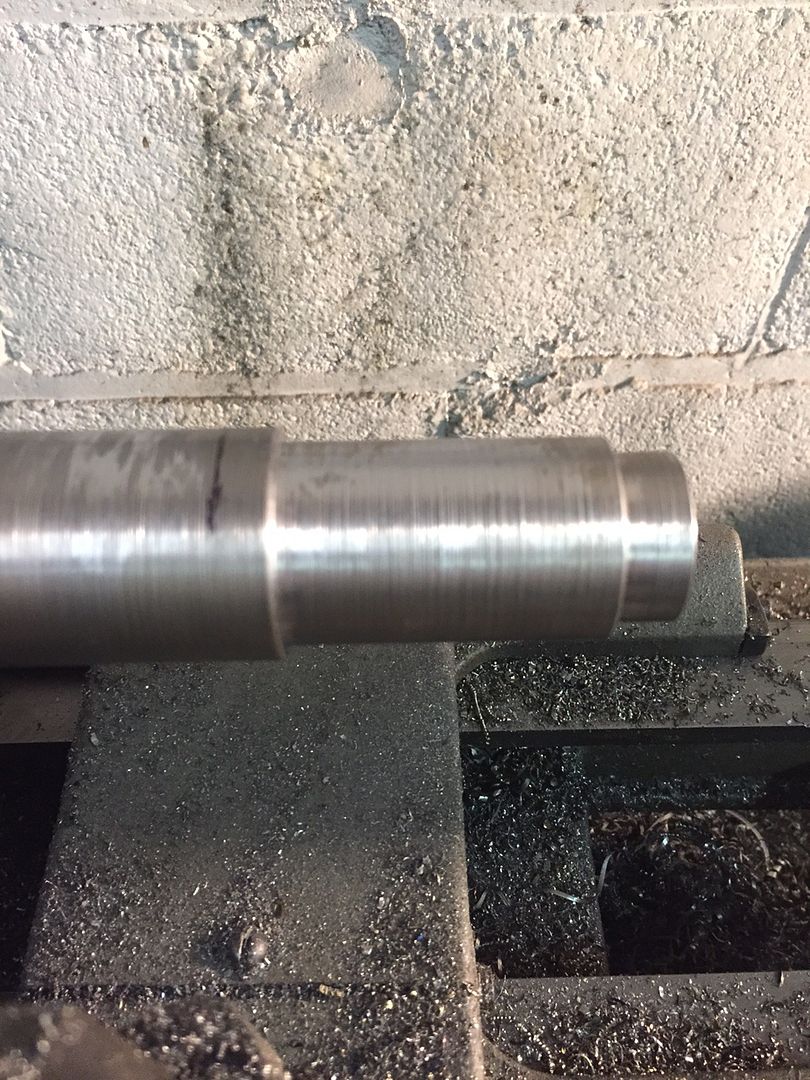

We started out by having a buddy bore the swingarm’s internal axle adjusters to match the cb750 bolt (I didn’t even own a mill yet). Then we figured out that a cbr1000f hurricane uses the same diameter rear axle we needed, yet definitely long enough (too long, in fact). So we tossed the bolt in the lathe to cut the shoulder back a little farther to add more threads to shorten the bolt later

after turning and threading, we have this:

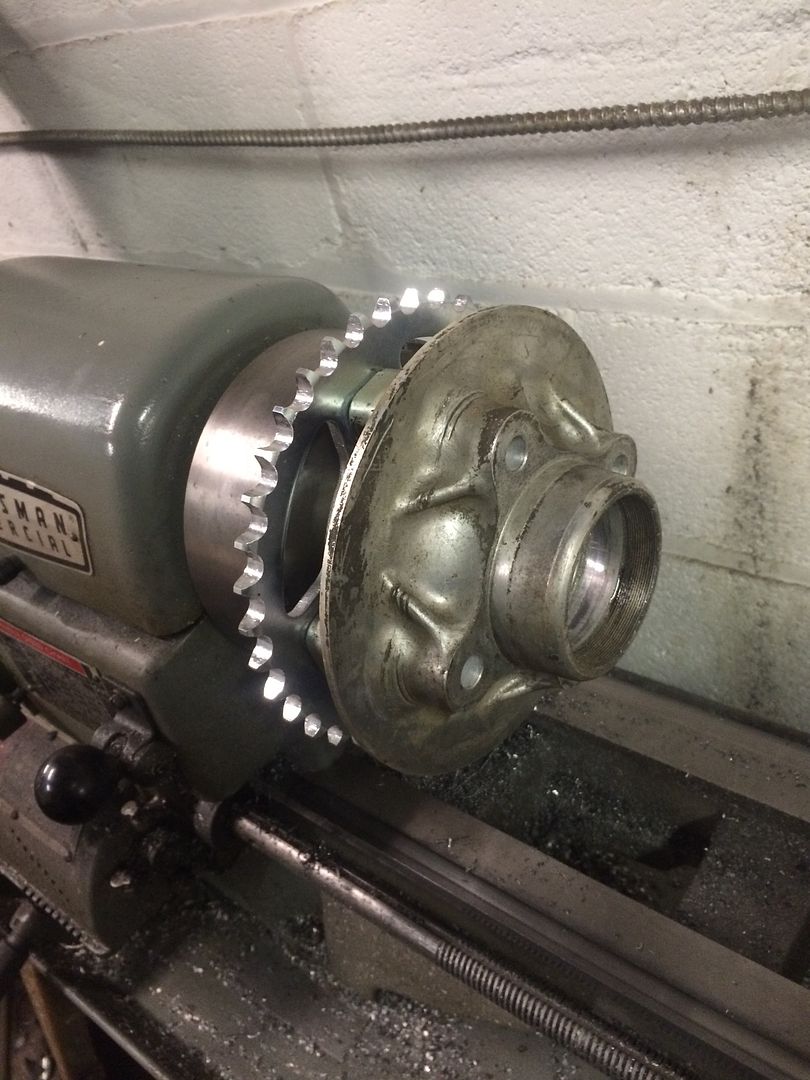

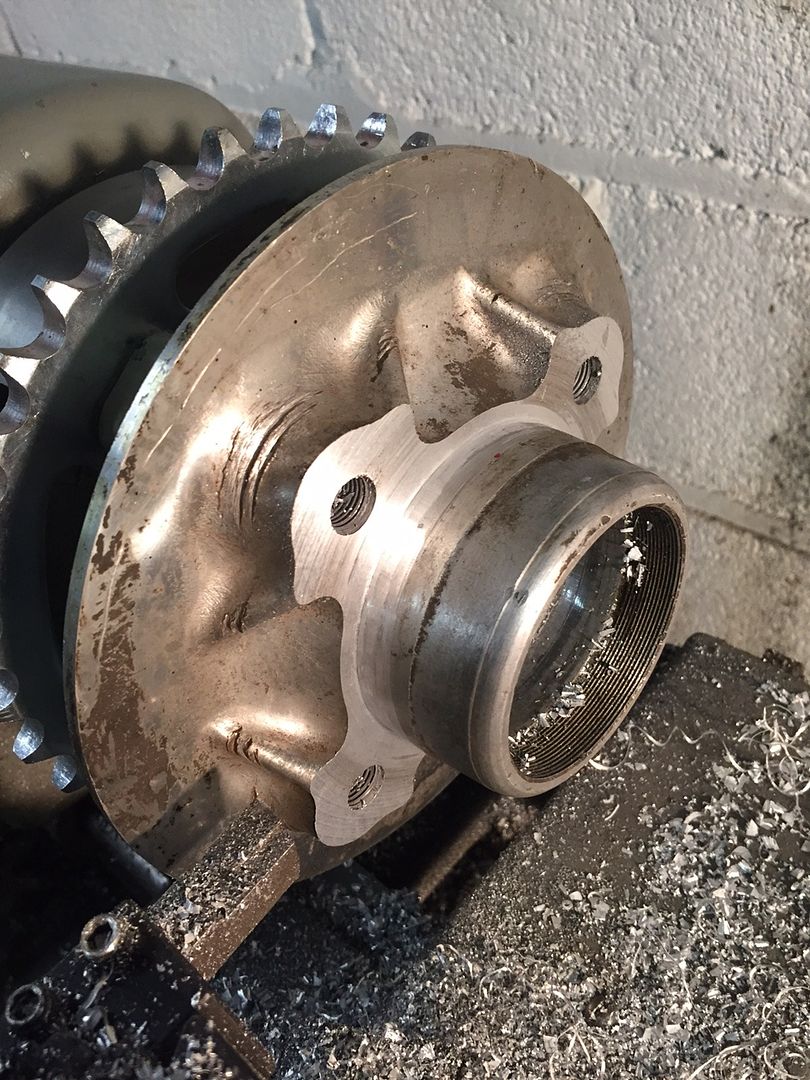

cool, so now we have to get the wheel centered in the swingarm. What was odd, is the sprocket lined up great, but the wheel wasn’t in the middle. so we shaved 8mm off the spacer for the axle on that side, and then had to come up with a way to chuck the cush drive in my lathe and take 8mm off that as well.

here’s after we took care of spacers:

Checko had a stroke of genius after we spent over an hour trying two different sets of jaws on the lathe chuck and various ways of mounting it…DURRR, flip the sprocket to the back and use that.

ahhh, there we are!

Then Checko made up some gussets for the area’s around the shock mount

and he designed and made up a battery box to go just at the rear of the tank above the carbs

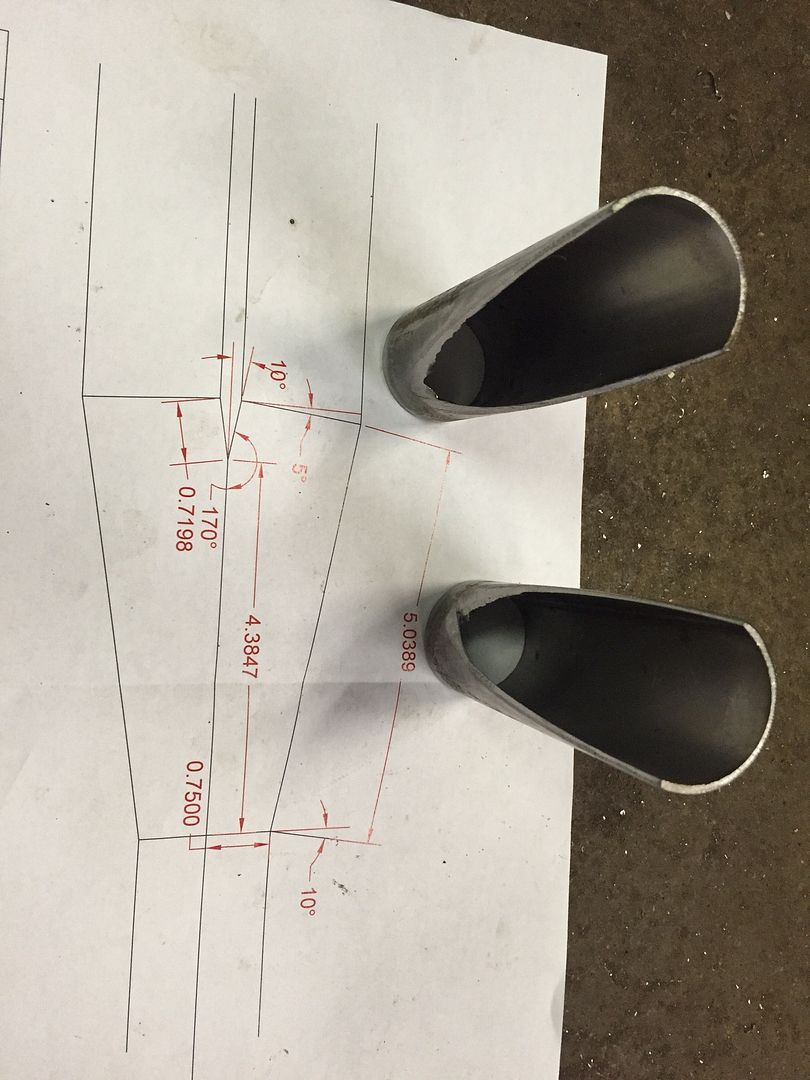

Time to move on to the front. Originally, the plan was to cut custom triple trees for these zx9r forks to retain factory geometry…but we realized the back is now longer, wider, and mono-shock…so factory geometry is kind of moot here…so we spend a good bit of time measuring and calculating and as it turns out, trail with the zx9r trees is 4.47" which is pretty acceptable.

so we pressed the stem out of the zx9r tree assuming we’d have to make a collar to adapt the stock cb360 stem…as it turns out, the I.D. of the zx9 stem was only 1mm smaller than the O.D. of the cb360 stem…so what we did was cut the zx9 stem flush with the top of the lower triple, then chucked it in the lathe, and bored it to press-fit the cb360 stem into it, then welded the two together at the bottom. Quick run to Buffalo Bearing for some stock-sized tapered neck bearings and bob’s your uncle.

Now that the forks fit the frame, time to make the wheel/axle fit the forks…

We had the zx9r axle to be able to replicate the ends, measured for what spacers would be required…and combined that to make the axle do both jobs in just two pieces. We cut spacers to run with a suzuki VZ800 front axle that was previous on this bike…but Luke traded away the VZ800 front end. Since the axle was still around and checko previously already swapped the bearings to fit that…here’s how it went.

Next checko made up a seatpan from some stainless he snagged out of the scrap bin where he works, compelete with blind hardware

And in some ebay searching, he snagged a yamaha blaster headlight, some Renthal Twin-Wall bars, and some 1-1/8" bar clamps. some measuring/drilling/hardware later we have this:

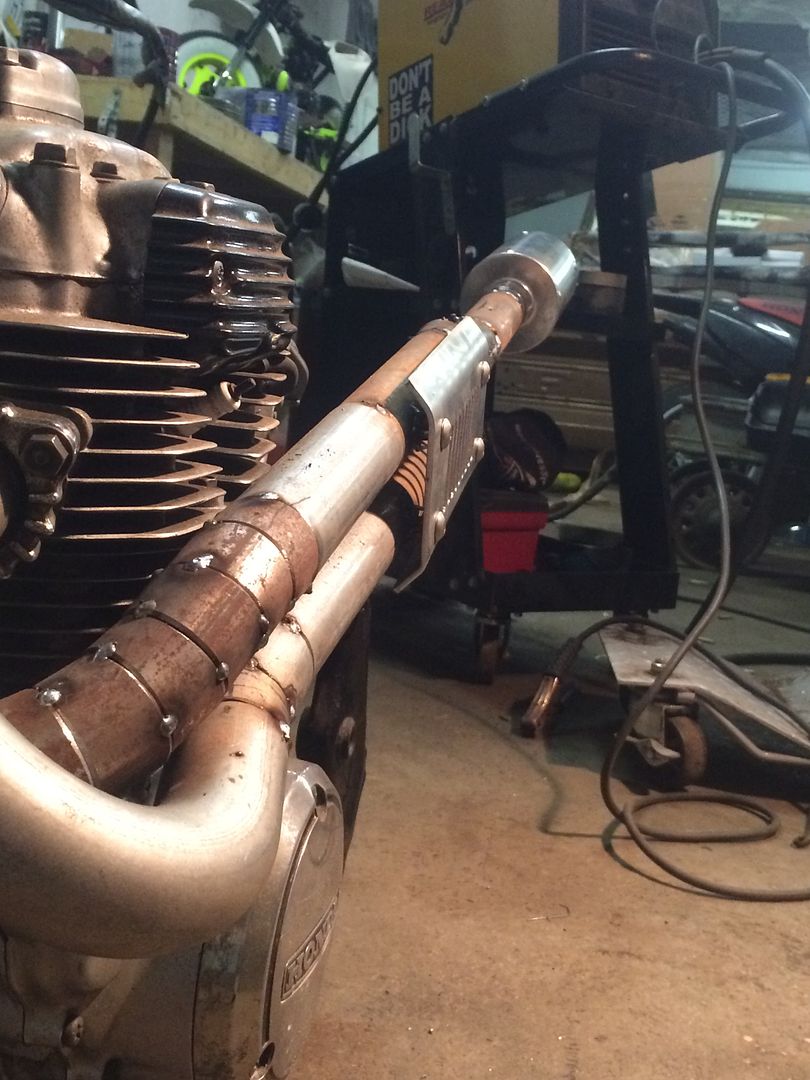

Next we decided to start planning out exhaust. We both liked the idea of scrambler style pipes to fit the dual-sport look/theme we’re kind of running with so far… Found some U-bends from a previous exhaust build while rummaging in our parts room and started mocking up a left side pipe

then, we were able to grab some cardboard to draw up how we’d be able to get the right sid to hug the front side of the frame down-tube and loop through this u-bend.

Set a 10’ length of 1.5" pipe up on saw horses and struck two chalklines 180* apart. set the bandsaw to 7.5*, and made cuts alternating 180* to achieve 15* per seam over an 8.5" radius to pie our way to greatness.

Checko laying the sparks

Then we both went to work the next day and did some non-work things at work.

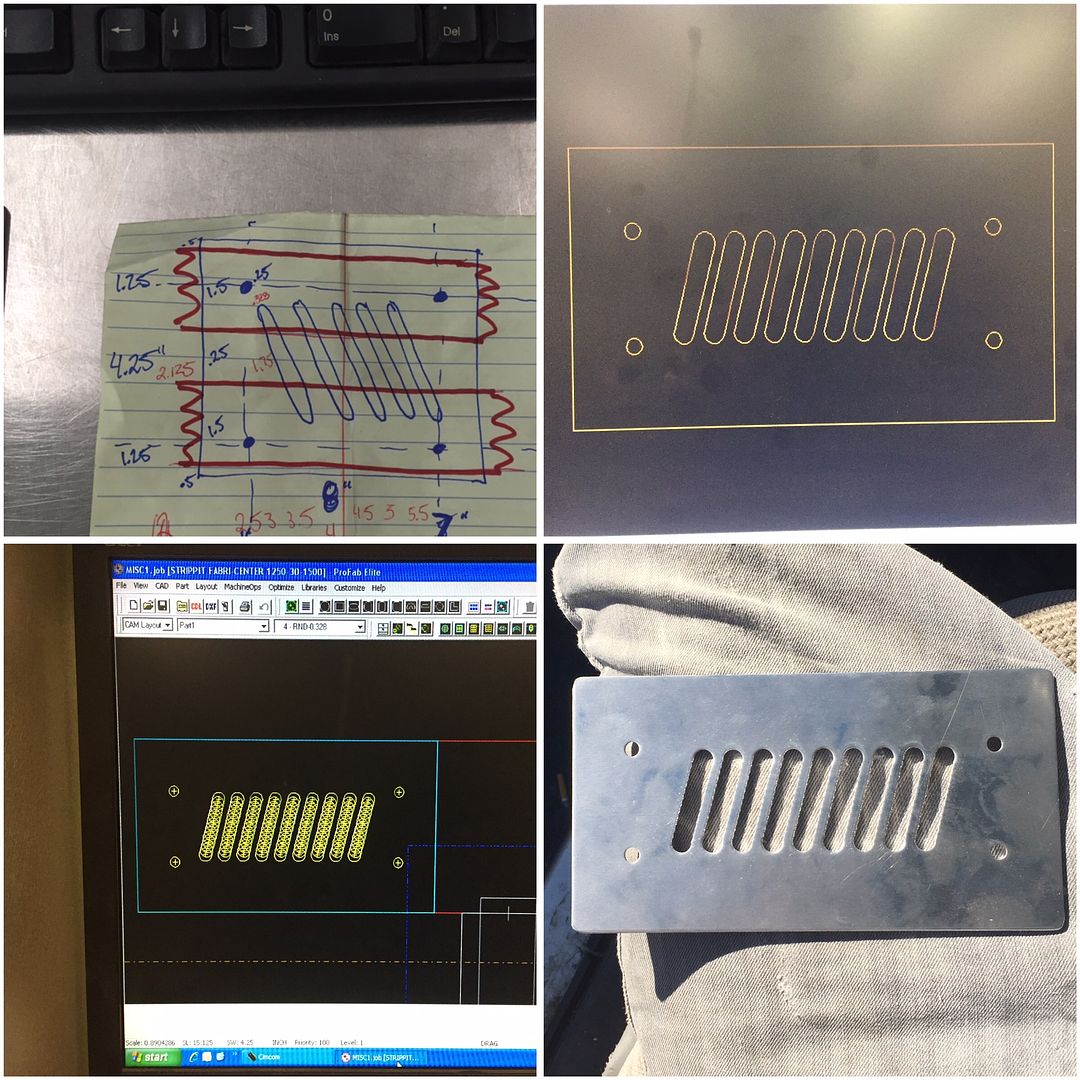

Checko took a sketch in and made up a heat shield for where your leg would lay across the exhaust.

I made up drawings for a collector, and that night we made up a jig from some scrap box steel to make the cuts on a chop-saw

We put some bends on the top and bottom of checko’s heat shield to get it to roll over the edges of the pipes, and welded on some nuts to hold the pipes parallel while we welded on our collector. Borrowed a muffler from one of the pitbikes for mock-up.

That pretty much brings us current. Checko grabbed an FMF can on ebay to finish up the exhaust, and we’re pretty much to the point of adding some gussets to the frame, and sending out a bunch of stuff for blasting so we can have @Kamilitaryman lay some siq powdercoat for us. Checko plans to order some dual-sport tires later this week, and we’ll probably break the bike down over the weekend to get upholstery and powdercoating taken care of, and bodywork/paint on the tank.

Current plan is a cream/off-white on the tank and rims, with brown frame and hubs, black spokes, and a tan seat.

Thanks for the post Pretzel.

Im stoked how much progress we made on this thing in no time. Can’t wait till its done. Along with your stupid truck so we can have shop space and build more bikes

Don’t worry, I have a stock of bikes we can build when this one is done and my truck is out. lol.

This looks bitchin’! Great job on the exhaust Checko! Now I have to stop by and check it out lol

So, now that the chain is all back in line, checko moved on to making up some frame gussets and welded those in.

Then started trying to pick frame and upholstery colors. going with the dark brown for the seat, gonna look for a tan color similar to the vinyl shown to do the frame. decided against dark frame color that’s on the paint cap in this pic

Then checko carved up some foam padding

Then setup the front end. Dual sport tire next to it is style we’re planning to toss on it after wheels come back from blasting and powder…had this used one kicking around just to look at.

then the whole thing was broken down to take a bunch of it to get media blasted

:tup:

lookn good

I honestly like all the color choices you have in that one pic. The dark brown reminds me of the Bonnevilles that were brown. Dark brown seat, that tan color for the tank, dark brown stripe in the center and maybe a pinstripe of orange on each side of the thick brown stripe?

tank is gonna be like a creme/off-white type color, glossy. frame is going to be probably pretty close to the light tan vinyl shown, and that same tan will be used for striping/accent/badging on the tank. the dark brown leather will be the seat, with tan stitching at 2" tufts. the rims will be the tank color, hubs will be brown like the seat fabric, spokes will be black. going to sodablast the engine to hell in hopes of bringing back clean aluminum. Checko sketched up a skidplate template last night that I’m gonna convert to autocad so he can punch it at work. paint and powder should be next week. between now and then we will probably finish weld the exhaust and wrap it, and mod the stock footpegs to accept dirtbike foot pads.

Whipped up a paint color for the frame/swing arm/wheel hubs.

@focusinprogress chime in with whatever colors we used

gonna run the dark vinyl for the seat

Tank/wheels in this color

made a skidplate with some 14g SS scrap from work, made another drawing on the computer and used the cnc turret punch machine to bang it out. Welded some t nuts to the frame and got some more torx SS hardware as well.

Paint is about a 70/30 blend of ford “dark cooper metallic” and some VW gloss black left from a mk4 tdi door I painted.

cnc turret punch?

checko works for E-one building firetrucks. He occasionally gets to whip some scrap through the machines on his breaks.

Hey Checko, is this the same 360 from a few years back or totally new?

@maxwell yes, same bike. Edsell explained it all in post #262

-

-

- Updated - - -

-

Google image, same machine, diff controller

33 stations with all sorts of diff shape punches, round, obround, squares, diff angle configurations etc

-

-

- Updated - - -

-

On on my breaks LOL

wow, that’s pretty baller.

It’s cool getting to know profab program and drawing the parts and making cool shit. Not the repetitive bs day to day

Painted the frame/swing arm/wheels/hubs with @focusinprogress last nite. Today we laced up the front wheel and mounted the tire.