get a wide band in the car and i will come plug in

do you have a fpr on the car…

do you have a wire tuck by any chance? if yes, check to make sure you have the injector clips on the correct injector. i have doen that before, it ended up being really rough.

6 pages and he hasn’t listened to joe yet? :slap:

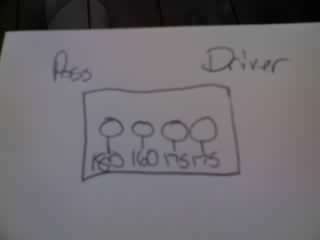

Ok… I did a comp check today. got a day off of work for once and was able to check it. Sorry about the sweet pic to. I am a artist what can i say.lol

cylinder #2 is starting to look weak, i believe specifications for variance is 24 psi…i’d say you’re on the verge of dropping cylinder #2.

True

OP: did you drip a tiny bit of oil in there to see if #2 would produce a higher number? 170ish isn’t awful, but more than 20psi variance between cylinders is not good.

damn this thread is still going?

pics of spark plugs

Your damn right it is JR. I cant figure my paper weight out. The plugs are black as hell. black as the nights sky. dont have a pic cause i cleaned them up

how much oil should i drop down #2?

if you’re plugs are extremely black, it’s a good indication you are running way to rich. This is a possible cause of burning up rings. I’m not sure how much oil to drop down, but i’m sure it’s nothing signifigant, can’t imagine it’s too much more than a few drops.

But i never had a prob before i got the headgasket, timing belt, intake mani, and trottle body put on.

Just a few drops will do it for compression testing, the compression inside the cylinder will force the oil onto the ring/cylinder and help temporarily seal worn rings. It’s really only useful to pinpoint rings, versus leaking valves or otherwise (i.e. if the comp number goes up, it’s def rings…but if it does nothing it is not ring wear)

Another question (assuming you did the compression test yourself)…how quickly did the needle rise as you cranked the engine over. Did it reach the max number quickly or slowly? Large jumps in pressure per crank, or no?

so its not compression.

something wasnt installed correctly.

chris u act like u aint paid. just do what u used 2 do back in the day when cobbs was around… hit up ur dad without him knowin for that loot and just replace the whole damn motor and call it a day haha… he sells so many damn cars im sure he wont notice it missin. he never did before…

did your head go to the machine shop when you did the headgasket? if not it’s possible that it’s slightly warped then.

no my buddy toby did it fo me. how could it be warped tho cause it ran fine before i got the stuff changed. never over heated one time ever.

if its just sitting there take the mani and tb. off throw the stock one back on and see what happens

you really dont have any downtime to lose its worth a shot it doesnt take that long to swap out

if that does nothing to correct it then keep looking

is it sounding like its misfiring or running rough or just blowing black smoke and running smooth?

for example, if you remove head bolts in the wrong sequence, it will warp the head. Its always important to wait till the motor is cool as well.

precisely, also could be done by not properly re-torqueing the head down.