I hit the car head on again tonight, the main goal was to install all the accessories and get all the wires hooked up.

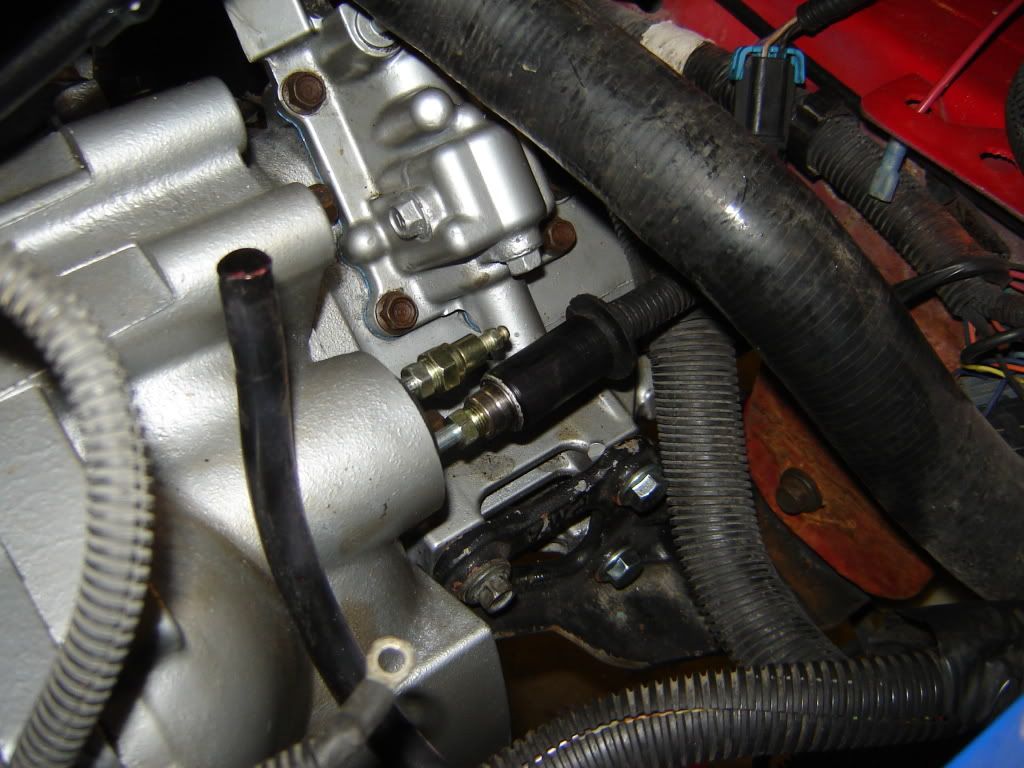

I was having problems getting the quick disconnect to lock into my new clutch slave cylinder, so thankfully the ends are interchangeable, and I just pulled the old fitting off and bolted it to the new slave cylinder. New fitting on the left, old on the right…

Finally connected

Bolted the header on, and got it all dirty…

Then I had to plug the EGR port in the intake manifold, since I don’t have one anymore, so I cut the end off of the line, crimped it, and used my new TIG to weld it closed. It’s temporary until I get the log manifold on.

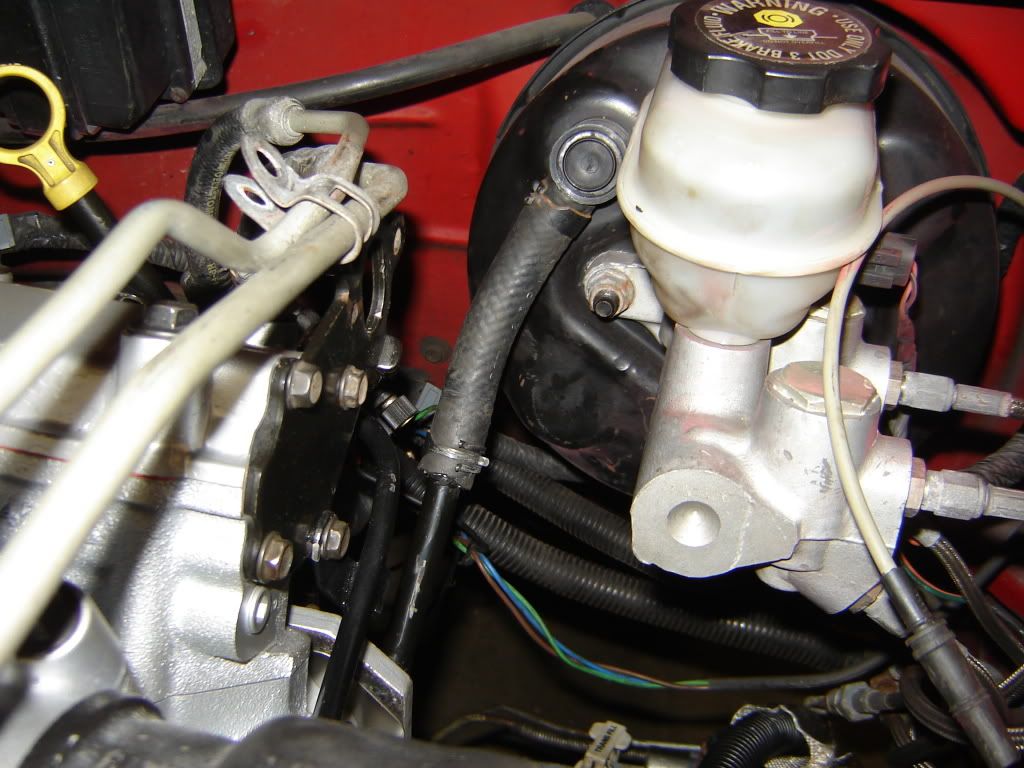

Installed the starter motor, alternator, intake and started running wires…

I never understood why this line was so long, it used to run to half way down the engine, turn around, and come all the way back. So I cut the hose to about 6" long and shortened the hard line and now its much simpler.

Started hooking up hoses, and realized that the heater core hose is right up against the header… so I’m going to have to find a way to tie it up away from the header and make a heat shield for it.

This is where I called it a night, I’m having problems finding my ICM… I seem to be spending more and more time looking for parts as the build comes to a close, haha

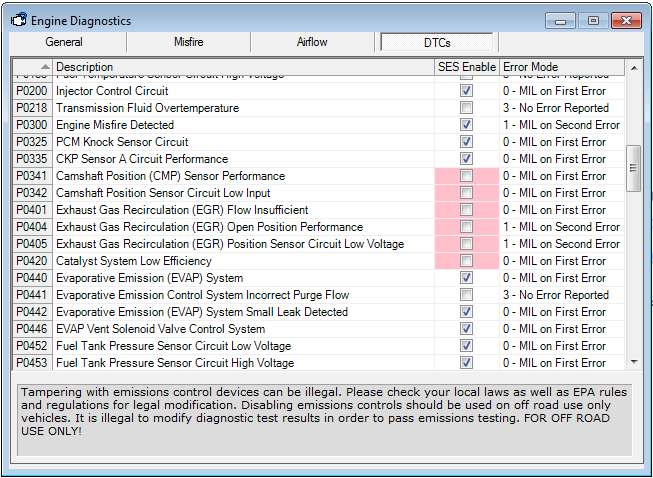

More tomorrow of course, hopefully once I find the ICM I can connect to the ECU and flash the new tune, as well as check that my wideband is actually going to log through the EGR.